Our DirectIndustry analyst has selected three new products by GEA, one of the world’s largest systems suppliers for the food, beverage, and pharmaceutical sectors, showcased at Achema 2024, the global forum for the process industries that is taking place this week in Frankfurt, Germany.

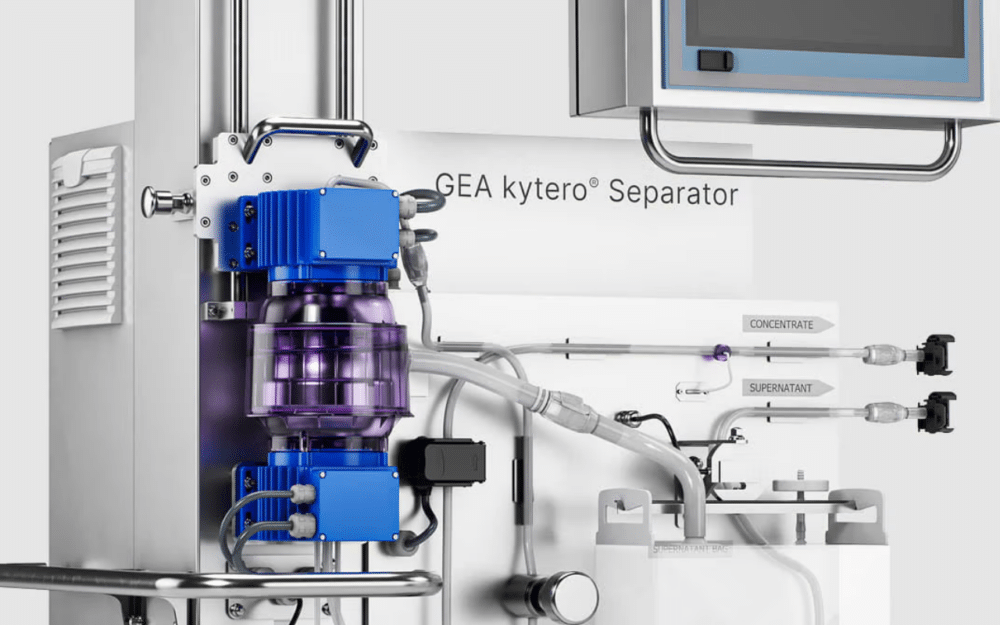

1/ The Kytero Separator

The GEA kytero® is a single-use pharma separator designed to reduce dependence on filtration processes.

Here are the key features:

- Cell Harvesting with Maximized Yield: The separator employs acclaimed GEA disk stack separation technology. This allows efficient cell harvesting while maximizing yield. This means better productivity and reduced losses.

- No SIP/CIP Required: Unlike traditional separators, the kytero® operates without needing SIP (Steam-in-Place) or CIP (Clean-in-Place). This simplifies the process and minimizes downtime between batches.

- Ready for the Next Batch in 5 Minutes: The kytero® offers rapid turnaround time. After one batch, it’s ready for the next production run in just 5 minutes.

- Available in Different Capacities: The GEA kytero® single-use separator is in a 500 L version, suitable for processing larger batches. Smaller batches can be upscaled to this capacity on the same machine. Additionally, the new GEA Kytero 2000 allows for further scalability.

2/ The OptiPartner

GEA OptiPartner is a digital software solution designed to provide increased process stability and optimum performance for spray drying plants.

Here’s how it works:

- Real-Time Optimizations: Every 20 seconds, the OptiPartner seamlessly adjusts your spray-drying production using a unique algorithm that draws on both hard and soft sensor inputs. These rapid adjustments lead to remarkable improvements over time.

- Benefits:

- Stability: Clients have experienced up to an 80% increase in stability.

- Capacity: Production capacity can improve by up to 10%.

- Energy Efficiency: Energy consumption reductions of up to 10% are achievable.

- Applications:

- Dairy and Food Ingredients: Producers of nutritional formulas, milk powders, and food ingredients can benefit by increasing residual moisture in powders.

- Chemical Powders: Quality improvements for battery materials, dyestuffs, and other chemicals.

- Instant Coffee: OptiPartner stabilizes the process, reducing disturbances and waste in instant coffee production.

3/ The NexGen Press®

The GEA NexGen Press® represents the next generation of tablet compression technology. It combines modular design, digitization, safety, ease of use, and ergonomic functionality. It is designed for pharmaceutical applications.

Here are the key features:

- Flexibility and Multifunctionality: Manufacturers seek solutions that handle both low and high-potency active ingredients. NexGen Press® simplifies machine selection, facilitates fast product changeovers, and delivers price-performance leadership.

- Intuitive Design: Each NexGen Press® benefits from a back-to-basics design philosophy, ensuring operational excellence. Safety, robust functionality, and customer support are standard features.

- Multiple Formats:

- NexGen Press® GMP: CE-certified, with a dust-tight enclosure. Upgradable for OEB 3 containment applications.

- NexGen Press® OEB: Offers both OEB 4 and 5 containment functionality, equipped with real-time monitoring and containment valves.

- Industry 4.0-Compatible: Digitalized and ready for connected environments.

- Plug-and-Play Options: Suitable for applications like orodispersible, MUPS, and bilayer tablets.

- User-Friendly HMI: Features multitouch functionality, interactive digital manuals, and online project documents.

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)