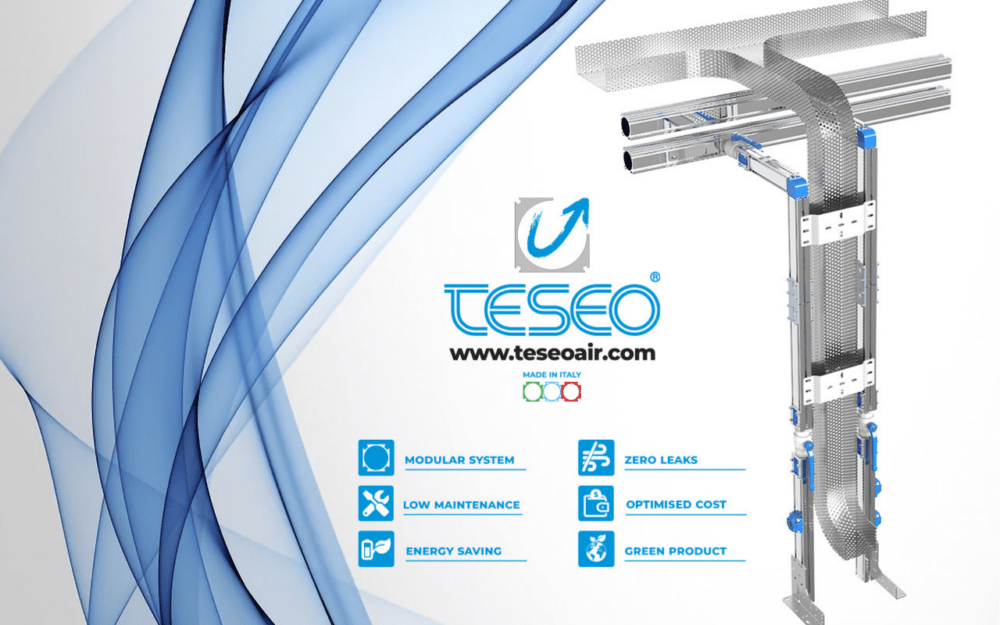

TESEO SRL was the first in the world to invent a modular aluminum system for compressed air distribution. It offers its customers not only piping but also a range of design services and customized ergonomic products such as swinging arms, drop columns, manifolds, workbenches, and trolleys. All are capable of transporting fluid energy. These products make up a complete system, optimizing functionality and costs.

Find out all about TESEO products at Hannover Messe, Hall 5, Stand A22, from 22 to 26 April 2024.

Content provided by Valentina Bonazza, Marketing Manager at TESEO SRL

Energy efficiency, at every stage of production, is now, more than ever, a priority issue for companies: rising energy prices, energy transition, and increasing production costs are some of the main factors that lead companies to look for cost-saving solutions, especially in the long term, while respecting the environment.

Energy Efficiency

In the production process, using a reliable system for the distribution of compressed air or pressurized fluids can make a big difference in terms of production efficiency. For more than 30 years, TESEO modular aluminum systems for compressed air and technical fluids (vacuum, mineral and synthetic oil, argon, nitrogen, carbon dioxide, and other fluids) have been a valuable asset to all companies wishing to work towards energy efficiency and sustainability, both environmental and economic.

That’s because TESEO has always had a strong environmental commitment before issues such as ‘zero impact’ and sustainability became key for most of today’s companies. Aluminum is a sustainable choice in itself, as is the modularity of the components, which makes it possible to modify, remove, or add elements to workbenches according to the customer’s needs even once it has already been installed: key features to avoid wasting energy, materials and money.

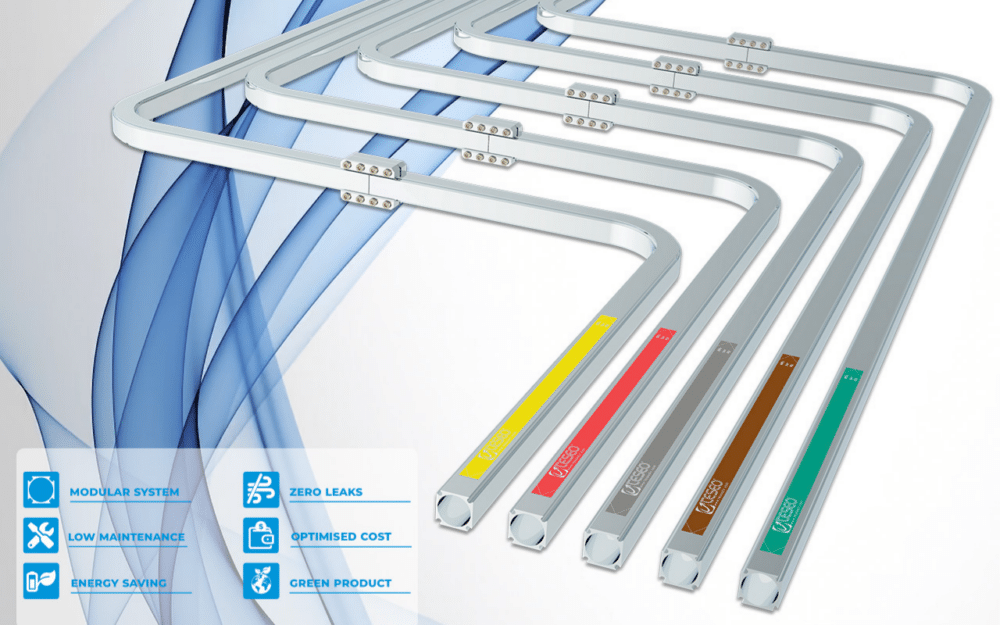

Moreover, TESEO offers customized piping systems in 100% natural aluminum, as well as in matte oxidized and anodized aluminum. Indeed, the company can also provide a wide range of special anodization upon request for several industrial applications. Design is another cornerstone of the Italian company TESEO, which regularly patents innovative, ergonomic and functional solutions with a visually appealing design.

Sustainability is achieved through experience, quality materials, and design

The distribution of compressed air for industrial automation is made up of many elements, which are often designed and installed without taking into account the bigger picture: the compressor room often runs separately from those who deal with the distribution system and from those who deal with the machinery that will receive the energy needed. An overall view of the system, like a conductor may have of the various instruments that make up the orchestra, helps to have a system that performs over the long term and at the same time is flexible, capable of adapting to the customer’s needs.

Aluminum a Sustainable Material

TESEO SRL is a historic Italian company that invented a market by developing the modular aluminum piping systems HBS, AP and AP Multi-fluid. It is now an international reference for compressed air and fluid power distribution. It offers customers not only piping but also consultancy, design and a wide range of products tailored to ergonomics, fully customizable, that integrate with each other and with the piping system to provide a complete system from the compressor room to the point of use.

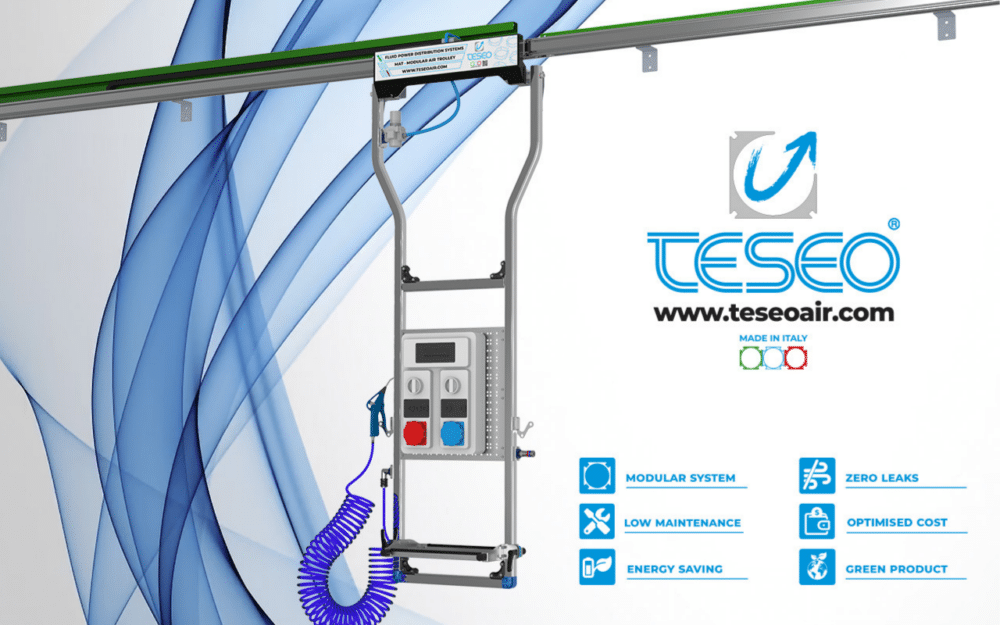

These include aluminum modular manifolds, drop columns and downpipe manifolds, and the ATS System, which consists of a rail on which a trolley equipped with a compressed air outlet and a tool attachment slides freely, allowing fluid and electrical energy sources readily available along the entire trolley travel. If fluid or electrical energy is to be supplied from above, not in a straight line but in a circular one, TESEO’s swinging arm supports for compressed air supply are excellent. They allow pneumatic tools to be supported and supplied on a circular or semi-circular surface, allowing very large working areas to be covered. Everything can be configured according to the customer’s needs. In addition, TESEO can provide customized workbenches (pressurized inside) and trolleys for automotive.

Applications

All these ergonomics products from TESEO cover a wide range of possible fields of application and areas of use. They often help to provide flowing power and electricity from above, avoiding any inconvenient pipes on the ground. They also contribute to the avoidance of waste and additional costs thanks to aluminum, a sustainable material in itself, and the modularity of the components, making it possible to remove or add elements according to the customer’s future needs.

This is complemented by an in-house team offering consultancy and design services with a view to corporate safety, energy efficiency and environmental and economic sustainability. Each TESEO plant is a tailor-made project, thanks to the in-house technical department that provides each customer with a specific design optimizing geometries and routes, to be up and running in the shortest possible time. TESEO provides customers with an energy-saving analysis service for their installations. In addition, each TESEO project is specifically tailored to meet each customer’s individual needs: whether it is a specific onboard application or a standard production line, TESEO provides specific plant design.

Training and Assistance

TESEO’s technical department also provides its customers with regulatory consulting and training of installation technicians. Supervision and assistance – from design to final testing – are provided to support the local staff carrying out the installation, while enabling the customer company to be operational in the shortest possible time. With more than 35 years of experience, TESEO provides its customers with complete compressed air piping lines by optimizing layouts to be as functional as possible. The main benefits of this service include constant monitoring of energy consumption, the possibility of modifying the installation, and thus increasing energy savings.

Find out all about TESEO products at Hannover Messe, Hall 5, Stand A22, from 22 to 26 April 2024

For more information: teseo@teseoair.com / www.teseoair.com

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)