Traditional QC in electronics is costly and complex. However, PRECiV™ software simplifies the process with AI-powered image analysis and user-friendly tools. This saves time and ensures accurate, repeatable defect detection. Its versatile observation modes and automation features enhance inspection efficiency and accuracy, ultimately improving your QC process.

Content provided by Evident

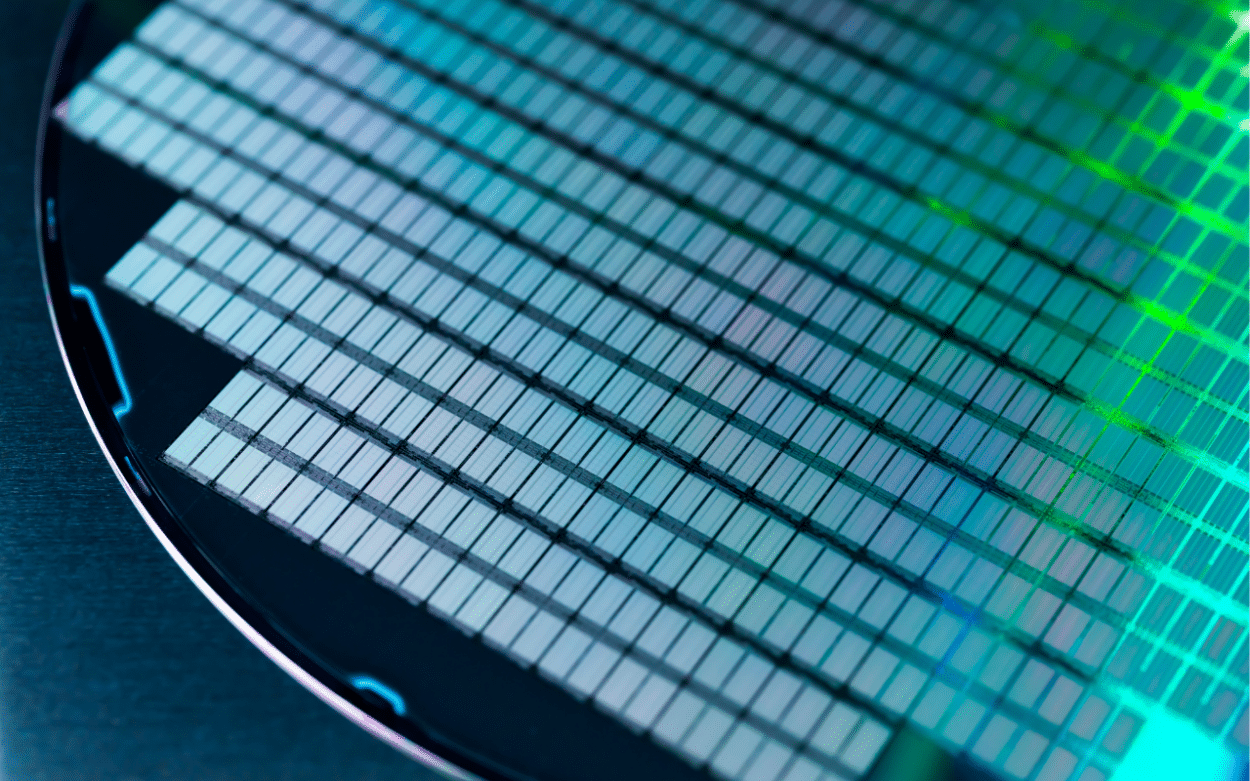

Microscopes are a fundamental part of quality control (QC) processes in the manufacture of semiconductors and electronic components. They ensure defect-free products that meet specifications and comply with international standards. From electroconductive contaminants on semiconductor wafers to the false positioning of components on PCBs, microscopes play a crucial role. They identify imperfections that could impact the functionality and reliability of electronic devices.

However, this QC process can be costly and time-consuming, requiring highly trained technicians and extremely accurate and reliable analysis. Recent advances in microscope software have been designed to optimize product inspection. The idea is to simplify QC workflows and enable accurate and reproducible measurements.

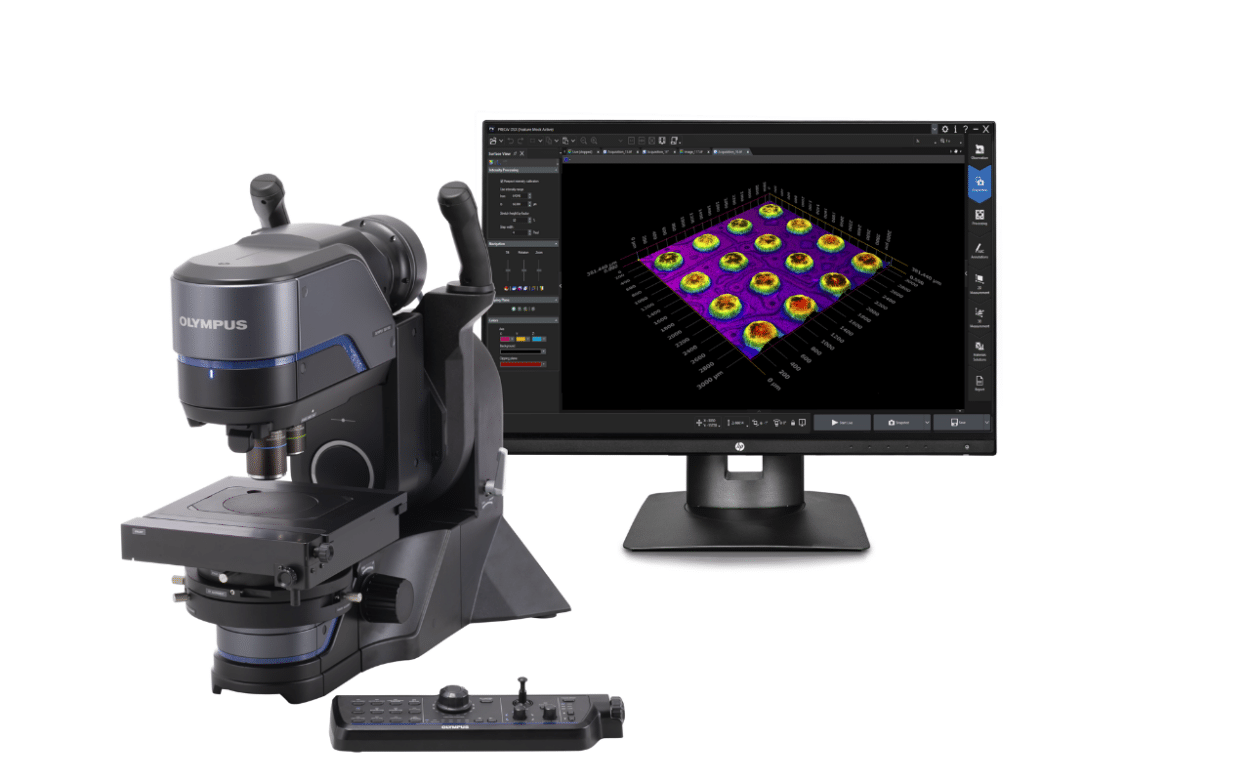

PRECiV™ software provides seamless integration into your QC workflow, decreasing flaw detection times and standardizing microscope operation for enhanced reproducibility of results, independent of the operator’s experience. Through its simple-to-use interface, AI-based image analysis, and integration with digital microscopes such as the DSX1000, the PRECiV™ software can quickly and accurately analyze a range of defects and variations.

Simplifying Your QC Workflow

Through a combination of a simple user interface and powerful functions like auto edge detection, the PRECiV™ software simplifies image observation, acquisition, and measurement on live and still pictures. The software’s extensive set of 2D count and measurement tools are essential for analyzing defects, enabling basic and advanced analysis of high-resolution images.

Advanced imaging features like extended focal imaging (EFI) and panorama are essential functions for thorough and reliable quality control. EFI captures crystal-clear images of uneven surfaces like chips, ensuring every detail is in focus. While panorama can seamlessly stitch together a complete overview of any component by manually or automatically moving the stage across the sample. Together, these functions ensure no defect goes unnoticed.

Furthermore, the workflow solution “NAVIGATE ON WAFER” can greatly simplify and speed up inspections for semiconductor wafers. Metrology inspections are usually conducted at several specific locations on the wafer, often requiring automated programs to improve inspection efficiency. However, setting up this automation can be extremely time-consuming, especially when programming the software to perform repeated inspections. With NAVIGATE ON WAFER, setup is quick and simple, providing a user-friendly interface with calibration and navigation options. Users can easily define the layout and alignment of the wafer by specifying three chip positions, allowing for accurate and repeatable measurements.

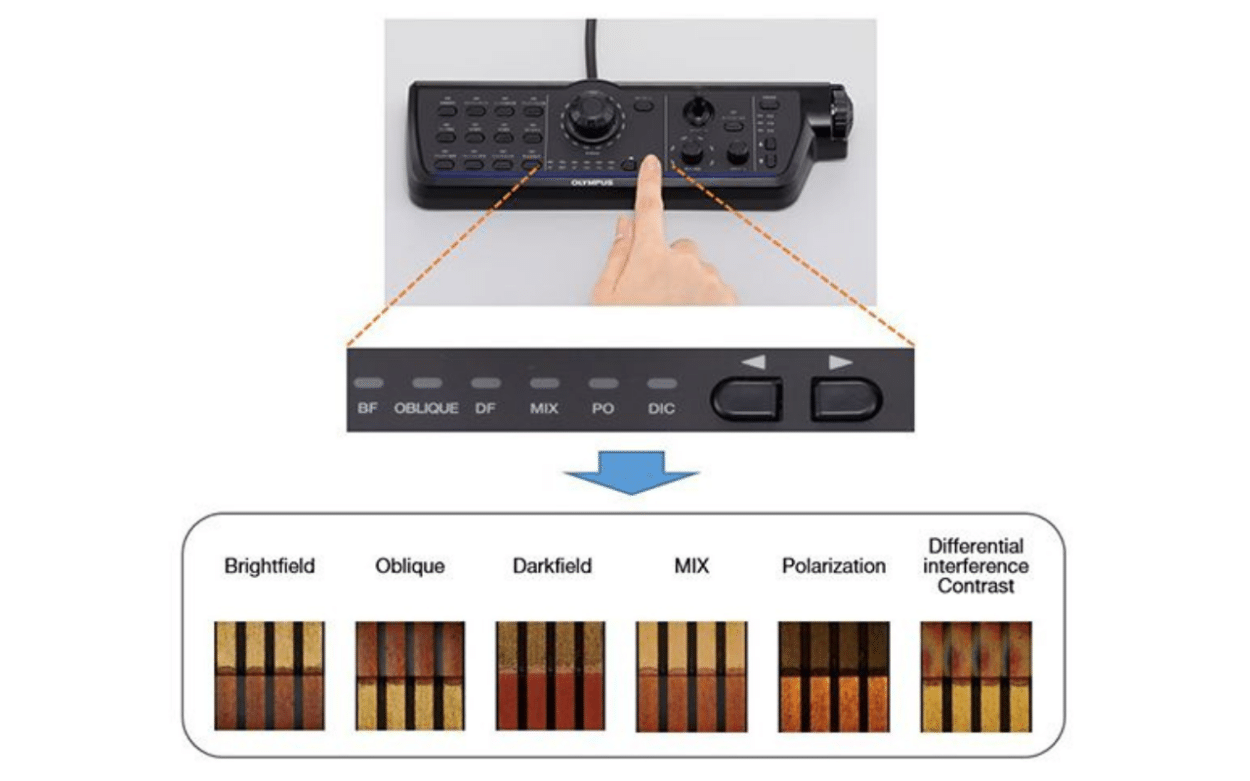

Optimizing Your Observation Mode

Due to the small size and complex nature of most electronic components, identifying imperfections and potential contaminants can be extremely challenging. The PRECiV™ software offers versatile and powerful image-enhancing tools that advance your inspection capabilities and significantly enhance your chances of detecting imperfections.

With a single click, the PRECiV DSX will display your sample image in six observation methods, including brightfield, darkfield, polarization, and MIX observation. MIX observation cleverly combines directional darkfield with other contrasts to reveal defects and differentiate surface variations that are normally challenging to see with conventional microscopes. Once chosen, the software automatically configures the microscope’s settings to optimize it for your sample, significantly reducing the inspection time.

Automating Analysis With TruAI™

Quantitative image analysis is a critical step in many quality assurance applications. However, conventional methods reliant on brightness or color for image segmentation often overlook crucial details or targets within samples—especially when performed by inexperienced users. Since image quality and contrast vary among samples, image segmentation using classical thresholding methods often lacks reproducibility and repeatability.

PRECiV™ software incorporates TruAI™ deep-learning technology, which utilizes artificial neural networks to analyze complex images quickly and easily. With TruAI™, users can apply a trained neural network to comparable images to automatically segment objects. Networks trained with instance segmentation offer the powerful capability to distinguish between touching objects with one click, eliminating the need to perform post-processing work. This helps users easily tackle complex applications in just one step while providing a more reproducible and robust analysis.

Enhancing Your QC Process

Implementing PRECiV™ software in an electronics manufacturing QC process gives users a range of tools to streamline inspections and save costs. With its user-friendly interface, comprehensive imaging and measurement solutions, and its AI-based automation, PRECiV™ software increases inspection efficiency and enhances the accuracy and repeatability of measurements.

Contact an Evident representative today to learn more about how PRECiV software can improve your QC process.

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)

![Image [Buying Guide] How to Choose the Right AMR?](/wp-content/uploads/sites/3/AMR-320x213.jpg)