Component inspections are critical to automotive manufacturing and maintenance processes, ensuring that machined parts and assemblies meet quality and safety standards. The complexity of modern automobile components, along with the burgeoning popularity of electric vehicles (EVs), has increased the demand for advanced inspection tools. Videoscope inspection systems can provide great value to a variety of core applications in automotive manufacturing and maintenance.

Content provided by Fayez Basheer Product Marketing Manager RVI at Evident

The Challenges Posed by Automotive Inspections

As automotive technologies evolve rapidly, machined parts are becoming smaller to improve vehicle efficiency. Automotive designs in general, are becoming increasingly complex, especially with the surging popularity of EVs. This complexity poses challenges for traditional inspection methods during manufacturing and maintenance, often necessitating destructive testing or disassembly.

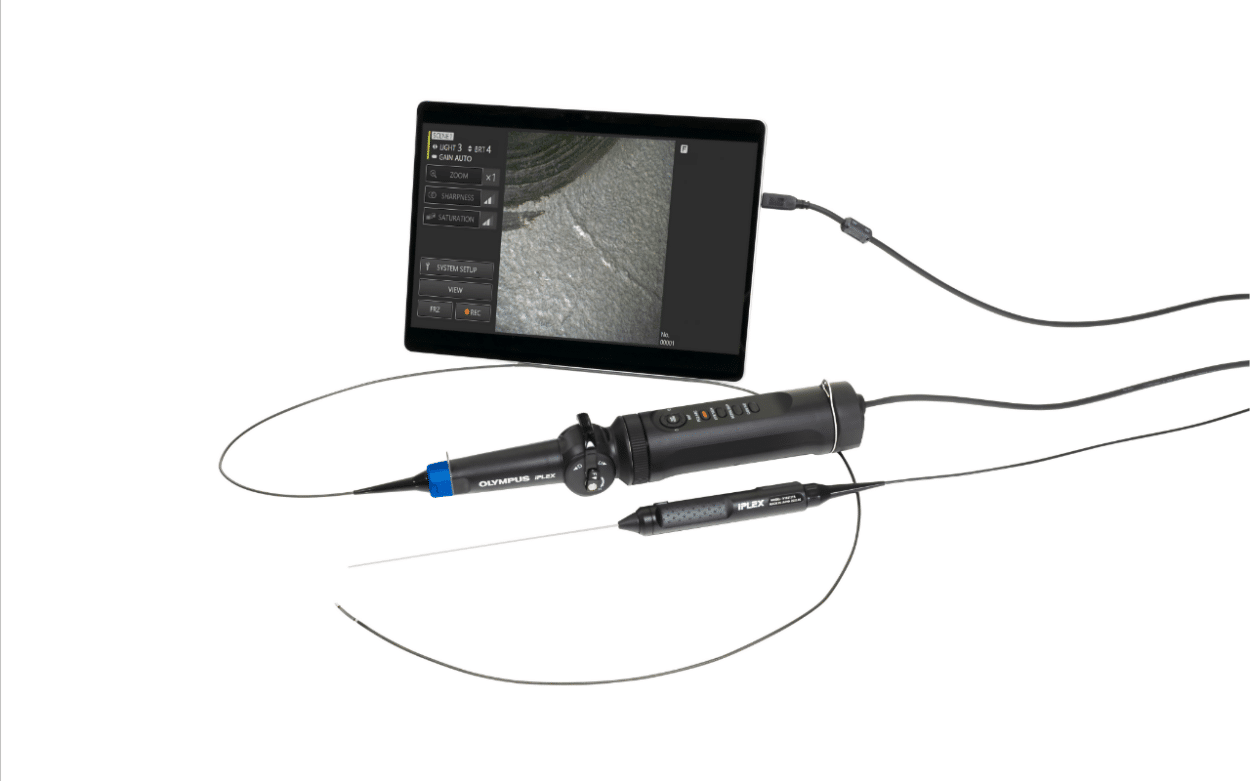

In response to the growing need for better inspection solutions, videoscope technology has emerged as a game-changer. Videoscopes leverage flexible insertion tube probes equipped with cameras to navigate and capture high-resolution images in hard-to-reach areas, allowing for remote visual inspection (RVI) of automotive components. The latest in industrial videoscope technology, the IPLEX™ TX II video borescope from Evident, comes equipped with ultra-thin diameter insertion tubes, enhanced durability, and a host of imaging features to streamline automotive inspections.

Videoscopy in Automotive Manufacturing

During automotive manufacturing, metal machined parts require meticulous inspection to ensure they meet the required level of quality prior to assembly. Inspections are generally implemented to check for burrs and residual sand that may remain after drilling or casting. Should burrs or residual sand be left behind, performance and safety issues can arise.

Inspections of metal machined parts have traditionally been carried out visually, forcing manufacturers to carry out random destructive testing of manufactured components in order to access key internal spaces.

Thanks to industrial videoscope technology, destructive testing of machined parts is no longer necessary. Providing visual access to intricate internal spaces, the IPLEX TX II video borescope features an ultra-narrow flexible scope with an outer diameter of just 2.2 mm—in contrast to the standard diameter of 4.0–6.0 mm. In addition, the IPLEX TX II has an advanced, short articulated tip that allows the scope to be easily inserted and flexibly manoeuvred in all directions, while a protective metal casing also reduces friction. This makes for a highly durable device that can navigate the tightest of spaces.

Combustion Engine and EV Maintenance

In addition to manufacturing, videoscopes are valuable for vehicle maintenance and diagnostics. Videoscope systems can easily be inserted into engine compartments, exhaust systems and other internal spaces, allowing for the convenient inspection of critical parts without the need for disassembly. The IPLEX TX II has a field of view of 120 degrees, significantly wider than conventional systems that offer 60–90 degrees. This allows for faults and wear to be detected with greater reliability.

Electric vehicles present unique challenges when it comes to carrying out maintenance inspections, with smaller and more complex components (mechanical and electrical) that require regular surveillance. One of the most important EV components that needs regular inspection is the inverter, responsible for supplying electricity to the traction motor that drives the wheels. Its inner workings, such as the circuit board, are only accessible through a very narrow opening.

The IPLEX TX II video borescope’s ultra-narrow scope makes easy work of navigating EV inverters and comes with imaging features like light intensity control, allowing for easy observation of soldering details in close proximity. This makes for a rapid and streamlined inspection process that saves time and money.

A New Era for Automotive Inspections

Videoscope technology is transforming our approach to daily automotive inspection tasks. Negating the need for destructive testing and disassembly, videoscopes provide convenient inspection of hard-to-reach spaces during manufacturing and maintenance. The latest in videoscope technology, the IPLEX TX II combines an ultra-thin profile with high durability and powerful imaging features to make automotive inspections easier than ever.

Find out how the IPLEX TX II can elevate your automotive inspections