Industrial cameras undertake a variety of tasks. Connected to the production line, they inspect products for deviations or defects, allowing them to be sorted out before leaving the production hall for shipment. How can companies leverage this technology to save costs and time, and what role does the industrial camera manufacturer IDS play in this?

By Claudia Kirsch, Product Communication Specialist at IDS Imaging Development Systems

Compared to the human eye, machine vision systems work faster, more accurately, and more reliably because they don’t miss any detail even at high cycle rates. In addition, employees can be relieved of “monotonous” and psychologically stressful sorting and inspection tasks.

In so-called embedded vision systems, the processing of the “seen” data as well as the resulting control takes place “on the device.” With embedded cameras, it’s also possible for derived commands to be directly transmitted to a robot. Therefore, the transmission of data and results to, as well as the evaluation by, an external PC becomes unnecessary.

Another benefit is that corresponding systems can be integrated into the production line in a space-saving manner.

Why AI is Pioneering New Frontiers in Image Processing

Industrial cameras with artificial intelligence (AI) go one step further. They open up completely new fields of application that cannot be handled by conventional image processing.

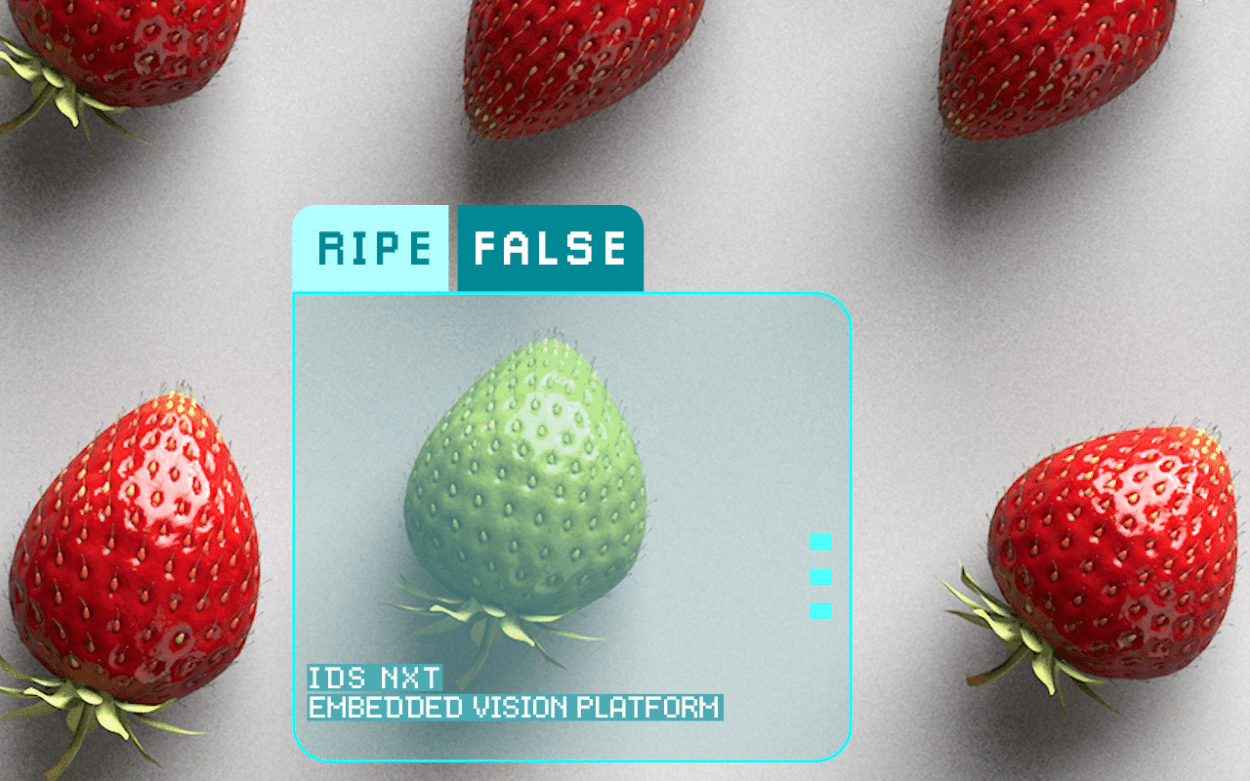

While many robots don’t understand their environment and can only work based on commands, AI-based systems enable them to react adaptively. This capability becomes necessary, for example, when recognizing and processing highly varying objects, such as food, plants, or other organic items. Characteristics like color, surface, size, or shape, for instance, exhibit significant variations in natural products.

However, AI can be trained to reliably recognize, categorize, and process a broad spectrum. For instance, if fruit needs to be sorted on a conveyor belt based on different quality characteristics, an industrial camera like the IDS NXT rio and rome models with integrated image processing can precisely distinguish “good” from “bad” or even other classes using artificial intelligence.

Taking Image Analysis to the NXT Level

How can a camera be taught to reliably detect deviations from the norm if they are not entirely predictable? Rule-based image processing might have to surrender, but with the user-friendly AI vision system IDS NXT, such a challenge can be easily overcome.

In addition, to object detection and classification, customers can now also utilize anomaly detection. The AI vision system IDS NXT can be operated quickly and easily by any user group, even without in-depth knowledge of machine learning, image processing, or application programming. Therefore, it offers an excellent way for the intelligent utilization of image processing.

Anyone who wants to explore the potential of cameras and AI for their own applications should take a closer look at the IDS NXT Experience Kit. From the camera to the software license, it contains all the components needed to create, train, and run a neural network on IDS NXT cameras. The use of Deep Learning-based image processing can, therefore, be evaluated and implemented in a short time.

For more information, visit www.ids-nxt.com