American technology company Honeywell introduced Digital Prime at the Honeywell User Group (HUG) conference in Orlando, Florida last week. Digital Prime is a digital twin solution designed to revolutionize the management of process controls and industrial systems. Deployed in the cloud, this solution offers users, particularly in the oil and gas industry, the ability to conduct more frequent testing while minimizing reactive maintenance interventions. Digital Prime is set to be available in the last quarter of 2023.

During the HUG conference in Orlando last week, Pramesh Maheshwari, President of Honeywell Process Solutions, delivered an opening keynote speech, introducing the company’s new Digital Prime solution. This new offering, set to be available in November, aims to empower industrial businesses with reliable and efficient cloud-based testing capabilities in near real-time.

According to Maheshwari,

“Honeywell Digital Prime is set to become a new benchmark for the digital twins of the future, providing instant access to a secure and real-time updated platform for monitoring and testing industrial operations.”

Always Up-to-Date: Ensuring Reliable Testing and Minimizing Disruptions

To prevent process disruptions and ensure safety, thorough testing is essential before implementing system changes. It is recommended to utilize systems that replicate the operating environment to create a secure testing environment without risking live operation disruptions. However, even with a lab system in place, failures can occur, and the modifications, updates, upgrades, and expansions may not be accurately reflected. Regular maintenance and updates are therefore necessary to keep the lab system aligned with the current operational environment.

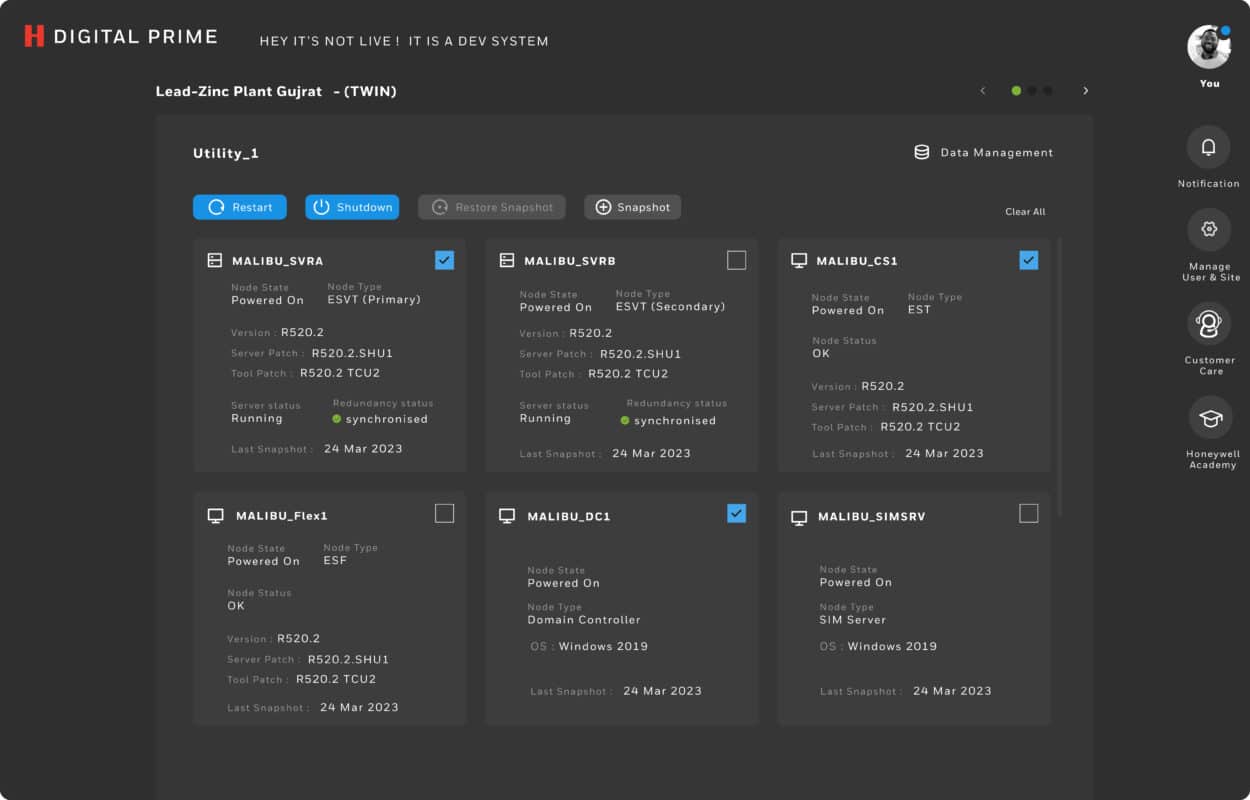

Addressing these challenges, Digital Prime provides a cutting-edge “lab system as a service” that continuously updates to reflect changes in the production environment, offering users a highly reliable digital twin.

Digital Prime offers an exact replica of the system, enabling users to promptly identify engineering anomalies and perform configuration compliance checks. This digital twin empowers users to effectively manage changes, conduct factory acceptance tests, and improve project execution and training, all in a collaborative and efficient manner without disrupting the normal operation of the production system. This prevents errors and issues that can lead to operational problems and inadequate control.

This new cloud-based virtual engineering platform is specifically designed for businesses operating in sectors such as oil and gas, sheet metal manufacturing, and chemical industries. In these sectors, developing engineering projects and testing modifications during planned downtime is crucial to minimize operational disruptions and service interruptions. This solution could bring many advantages to these businesses.

Ensuring Robust Cybersecurity

During a press conference at the HUG event, Tiffany Barnes, Senior Offering Manager at Honeywell, highlighted the platform’s strong cybersecurity features.

“We started with a holistic cyber secure platform, leveraging our expertise in Digital Twin technology for over 15 years. Recognizing the increasing importance of cybersecurity, we developed a platform specifically tailored to this environment. At the customer’s site, the installed hardware components connect to a cyber-secure remote infrastructure, where all data resides. To ensure secure access, we utilize a single sign-on capability, allowing customers to log in from anywhere globally. The virtual infrastructure, located behind Honeywell’s virtual network, remains completely isolated from the internet, guaranteeing data security.”

A Comprehensive Ecosystem for Operational Excellence

Digital Prime is not just a standalone solution; it is part of a broader ecosystem designed to enhance operational excellence. Through this online platform, users have access to a virtual laboratory where they can test, simulate, and optimize their operations. They can seamlessly adapt to software and hardware changes, without the need for expensive hardware upgrades.

By leveraging a centralized cloud infrastructure, Honeywell aims to eliminate the traditional challenges associated with hardware upgrades and maintenance. Unlike physical upgrades that require significant resources and time, the cloud-based model allows for centralized updates to be seamlessly pushed to end users, ensuring they have immediate access to the latest features and improvements. This results in cost-saving benefits and a streamlined update process.

“For customers who have a hardware-based approach, they often face challenges. Their development system may be left in the dark when production undergoes upgrades or changes. They tend to scale only a subset of their clusters or releases, limiting their ability to maintain different releases across their enterprise. However, in this digital space, there are no such limitations holding them back. It is a scalable and agile space that can accommodate changes at any time.”

Control Simulation and Collaboration Opportunities

In addition to digital twins, Honeywell provides control simulation capabilities, allowing customers to test their engineering strategies without the need for physical hardware, Tiffany Barnes continues:

“This offline system allows customers to observe their control strategies running and perform testing of graphics and engineering configurations in a simplified, low-fidelity environment.”

The Digital Prime ecosystem also expands collaboration opportunities by offering a centralized location for data sharing, decision-making, and actionable insights.

“Collaboration is a significant feature that enables end users to store and share data, track individual contributions, and have a centralized location for decision-making. Our customers seek a platform where they can access data and make informed decisions in a cohesive manner. Moving forward, we aim to provide more actionable insights within this space.”

The platform also provides flexible training options to bridge the skills gap. It accommodates end users who may not be familiar with the system, whether they are new engineers or those transitioning from another company’s system.

User Testing

Honeywell has engaged with a select group of customers for beta testing and gathering feedback on Digital Prime. Approximately six customers are actively involved in piloting the platform, providing valuable insights on licensing, functionality, and overall user experience, explained Tiffany Barnes.

“A major chemical company in the United States has already leveraged Digital Prime to address their challenges. They were facing an upcoming migration and needed an environment for testing applications and HMI. Cost-effectiveness and the ability for multiple users to interact were key requirements. Within just two weeks of approaching Honeywell, the company provided them with a virtual infrastructure solution through a simple subscription that required no hardware. Honeywell quickly approved logins for as many concurrent users as needed. This seamless setup allowed the company to approach their migration more prepared, without leaving the controls piece for later. Their positive experience has led them to request additional systems, which are currently being piloted.”

According to Honeywell, Digital Prime has the potential to help companies achieve significant improvements in their operations, including a 40% reduction in failure rates, a 20% reduction in repair times, and a 70% reduction in preventative maintenance.

The primary prerequisite for utilizing Honeywell Digital Prime during its initial launch is being a Honeywell customer and utilizing the Experion PKS release.