In the highly competitive $28.5 billion movie industry, filmmakers are constantly seeking ways to innovate and push the limits of technology to create awe-inspiring shots and sequences to impress both critics and audiences. SnorriCam’s custom professional camera rigs for both indie projects and global blockbusters are manufactured with the help of Hubs. The company leverages automation to allow fast and affordable access to manufacturing capabilities from all over the world.

Content provided by Hubs

Both avid cinephiles and occasional moviegoers have encountered films featuring SnorriCam shots. This innovative camera has left a lasting impact on film history, adding to the intensity of Darren Aronofsky’s first film “Pi” and capturing dynamic close-ups of Tom Holland and Zendaya in “Spider-Man: No Way Home.”

Making its Way to Hollywood

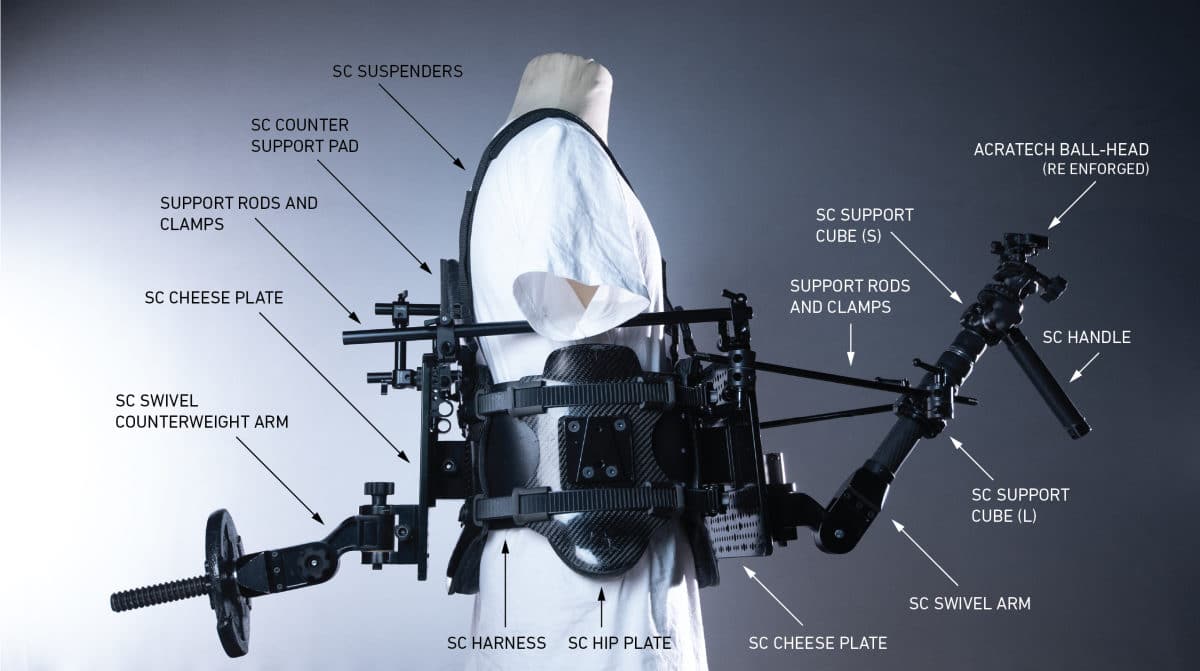

The SnorriCam is a camera rig that attaches to an actor’s body to capture immersive point-of-view shots. It was developed by Eiður Snorri and Einar Snorri in the 1990s and soon gain popularity, and eventually made its way to Hollywood blockbusters.

In its current iteration, the SnorriCam rig comprises a standard body harness that can be fitted with many different types of camera arms for different kinds of shots and filming techniques. When commercializing this idea, Eiður turned to distributed manufacturing platform Hubs for their expertise. The collaboration not only helped Eiður speed up the development process but also reduce manufacturing costs.

Why CNC Machining?

A SnorriCam rig needs to safely attach to an actor’s body, allow for a dynamic range of motion, swivel, and lock seamlessly, all without dropping a 5 kg camera. This requires sturdy and high-tolerance stuff, which makes CNC machining the perfect fit for the job. According to Eiður,

“When you swing the camera back and forth, it creates an unbelievable amount of force. All the locking mechanisms had to be crazy strong to keep the camera from flying all over the place.”

He adds that the camera itself isn’t fixed, but can swivel for a broader range of coverage. One of the key components of the SnorriCam is a proprietary locking system called the V-Lock, a critical pair of parts that have to fit together accurately. All parts must be tightly toleranced to ensure the entire rig can hold the camera in place and swivel to achieve a variety of camera effects, all while safely harnessed to an actor.

“If they were too loose, the camera would wobble, and if they were too tight, the mechanism wouldn’t fit together. You have a very expensive camera at the end of it, so it has to be perfect.”

As a customizable, complex, and niche industry product, the rig is constantly undergoing design iterations, and the device itself comprises a huge number of metal parts that need to fit together perfectly.

While Eiður first worked with traditional manufacturers, this approach meant having to put up with weeks of waiting for quotes and exorbitant costs. Both factors were major hindrances to perfecting the design for use and manufacturability. That’s when Eiður turned to Hubs. The ability to upload several CAD designs and compare materials and prices, significantly accelerated Eiður’s ability to innovate.

Hubs’ Design for Manufacturability (DoF) tool enabled SnorriCam to prepare its designs for production runs, Eiður explained:

“I was able to make certain parts exactly as I wanted to and also save money.”

Presently, Hubs supplies all the metal parts found on the rig, including cheese plates, specialized pins, knobs and wingnuts, arms, swivel mechanisms, support cubes for the arms, and many other complex components. For time-sensitive CNC projects, Hubs offers local sourcing options with lead times as short as 5 days.

With Hubs taking care of the production, SnorriCam could focus on improving its designs. The company is also exploring the idea of a potential prosumer device that’s more affordable for smaller production companies and indie filmmakers.

Hubs CEO Alex Cappy commented:

“Many of us appreciate the visual artistry of movies but may not realize the technological advancements that make it possible. The SnorriCam is a prime example of this, demonstrating how CNC machining can be used to create impactful cinema while also saving time, and money, and providing more design freedom.”