On the occasion of our special focus on China’s industry, we are presenting different Chinese companies in various industrial sectors. In this article, we focus on Accurl, which manufactures press brakes and laser cutting machines. Kevin Tai, Sales Manager at Accurl, tells us more about the company.

This interview was conducted in collaboration with VE China.

Can you tell us more about your company’s history?

Accurl is a leader in the sheet metal processing machinery industry and has been building the brand since 1988. Our customers are located in more than 100 countries.

What are your main products and innovations?

The first production of Accurl was a manual sheet cutting machine. Nowadays, Accurl is offering a wide range of products in the sheet metal working industry. The main technologies we offer are:

- Laser cutting technology

- Punch and forming technology

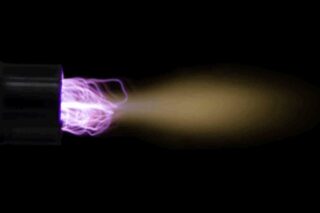

- Plasma cutting technology

- Bending technology

- Cutting technology

- Combined shearing technology

- Programming systems

- Automation technology

In terms of innovation, our engineers from Germany specialize in designing machine styles and our domestic teams are constantly improving technology research and development.

We have developed a new type of bending machine which has the following characteristics:

- Professional bending laser safety optical safety device, the highest level of safety and operator protection

- New servo energy saving and environmental protection function, energy saving 65%, noise less than 57 decibels.

- Professional bending deep box solutions, professionally customized according to customer needs.

What is your latest machine?

Accurl will officially display the heavy-duty full electric servo press brake (eB Ultra Series) at the Hannover exhibition in October 2022. This full servo electric press brake, combined with the four characteristics of “energy saving, environmental protection, high efficiency, and high precision.”

This model is only 25% of other electro-hydraulic servo models. It does not use any hydraulic oil so there is no need to change the oil. This means there is no pollution caused by oil leakage so the workshop is always clean and tidy.

The fast full-speed conversion and bottom dead center positioning of the heavy-duty full electric servo CNC bending machine are controlled by the servo motor and screw rod. The control of the whole cycle is much faster than that of the hydraulic bending machine

This machine mainly relies on the servo motor and screw drive to make the sliding plate move up and down and position. After long-term use, positioning accuracy can still be maintained.

What are your expectations for your future prospects?

In the long term, the launch of Accurl’s machine will be an important step for the domestic CNC bending machine field to officially enter the “new energy era”. If the manufactured equipment is not accepted by the market and the customer, cannot enter the factory, or play a role in the production line, then the technology is only in vain.

Accurl has always adhered to the production concept of creating good quality and durable sheet metal processing equipment. Accurl hopes that the heavy-duty full electric servo CNC press brake introduced this time will enter more factories and continue to pass on our belief.