IMTS, The International Manufacturing Technology Show, is coming back today in Chicago and will run until September 17. The fair will feature the latest innovations in digital and traditional manufacturing and help industrial leaders solve their manufacturing challenges and improve efficiency. Hybrid manufacturing is among the biggest trends this year with the collaboration between Autodesk and Philipps Corp.

Adoption of hybrid manufacturing technology has remained low, but pioneering solutions are now emerging, according to Robert Bowerman, Senior Technology Consultant at Autodesk.

Improving accessibility in both software and hardware has been key, he stresses – and in this area, the technology giant has collaborated with Phillips Corp with great success.

“At Autodesk, we have been involved with directed energy deposition (DED) and hybrid technology for the best part of a decade, offering software solutions to drive hybrid machines with our PowerMill product. Traditionally, due to the high barriers of entry within the technology: the inaccessibility of machines and software and the knowledge required to be successful with the technology, to name a few, the technology’s adoption has remained low and limited to more advanced industries and larger organization.

More recently, however, accessible solutions in software and hardware have come to market.

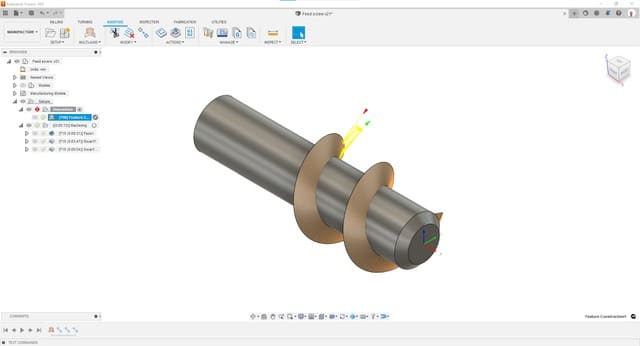

“The Phillips offering of a hybrid machine, within a common, well-known Haas machine platform and Autodesk’s connected CAD-CAM within Fusion 360, is a combination that sets a new standard for accessible hybrid manufacturing.”

The Advantages of Hybrid Manufacturing

Hybrid manufacturing brings additive manufacturing and subtractive manufacturing together within the same machine, offering the potential to produce and repair finished components inside one piece of equipment.

It can reduce the cost of materials, offer time savings – as it minimizes the need to switch machines – and bring great flexibility and specificity in combining different metals.

Autodesk and Phillips now hope their combined experience and collaboration will encourage greater adoption, says Mr. Bowerman:

“Phillips Corp has been a Haas Factory Outlet for over 30 years with over 18,000 machines installed – this brings unrivalled experience in the industries they serve and reach to users as well as experience in the machine platform. Autodesk’s Fusion 360 has a rapidly growing user base amongst Haas users, offering a powerful, easy to use, integrated workflow from design to manufacture.

This combination of technology, Mr. Bowerman believes, will conquer new sectors and user groups who previously would not have been able to explore the benefits of such novel technology.

WATCH ALSO

A Single, Integrated Environment

With Fusion 360, a user is able to design, simulate and manufacture their products in a single integrated environment, he continues:

“Recently, we have added new multi-axis additive manufacturing toolpaths to Fusion 360 that are specifically aimed at driving a Hybrid DED process on three and multi axis machines. In collaboration with Meltio, Phillips has developed a Haas machine integration that ensures users will be up and running with hybrid technology on their new or existing Haas platform in minimal time.”

He says hardware and software often live in independent silos:

“This can lead to machines and software that do not perform as expected and a lot of frustration for the end user. Collaboration, such as that between us and Philips brings so much more clarity and added value to the complete solution, which ultimately is a win for all.”

Mr. Bowerman believes hybrid DED technology has the potential to revolutionize the way many products are manufactured and repaired. However, there are many challenges that must be overcome before wider adoption is likely, he adds/

“These challenges are multi-faceted and can’t be conquered by one party alone, hence, we’re always looking to collaborate with those who believe in the benefits of the technology and have the desire to drive its adoption to achieve greater usage throughout industry.”

![[IMTS 2022] A New Standard for Accessible Hybrid Manufacturing](/wp-content/uploads/sites/3/2020_1113_meltiousa_fall2020machine_keylimephoto_113-1250x860.jpg)