By Danding Liu, Marketing Coordinator at Han’s Laser

Han’s laser automation solution for perforated tubing manufacturing in the Daqing oilfield effectively solves the problem of deformed contours and improves production processes.

Perforation is an essential technology for petroleum products and a key factor that affects oil production efficiency and output rate. Perforation gun tubing is a key element of perforation technology. It holds gunpowder and keeps everything in its place. Perforation guns are usually made of metal tubes, plastic, paper rolls, etc. The design and quality of the fabrication of perforation guns determines the explosion point’s accuracy and the power of the explosion.

Previously, metalworkers mainly used stamping technology to manufacture perforation guns, which meant the efficiency depended on the degree of die customization for various hole diameters and positions. With this technology it takes the manufacturer a lot of time and human resources to repeatedly position and clamp the tube to process one perforation gun, which is inefficient. Additionally, tailor-made dies are consumable. Overused dies cause low accuracy, defective products and less flexibility throughout the whole process.

Han’s Laser tube FMS achieves accurate laser cutting with a contour that is so accurate it reproduces the same shape as the one outlined by software. P6018D brings users breakthrough manufacturing techniques including high-speed tube cutting, instant scrap-dropping, etc. The nesting software generates NC programming automatically, the machine processes complex tube contours in a single clamping and achieves fully automatic loading and unloading of materials.

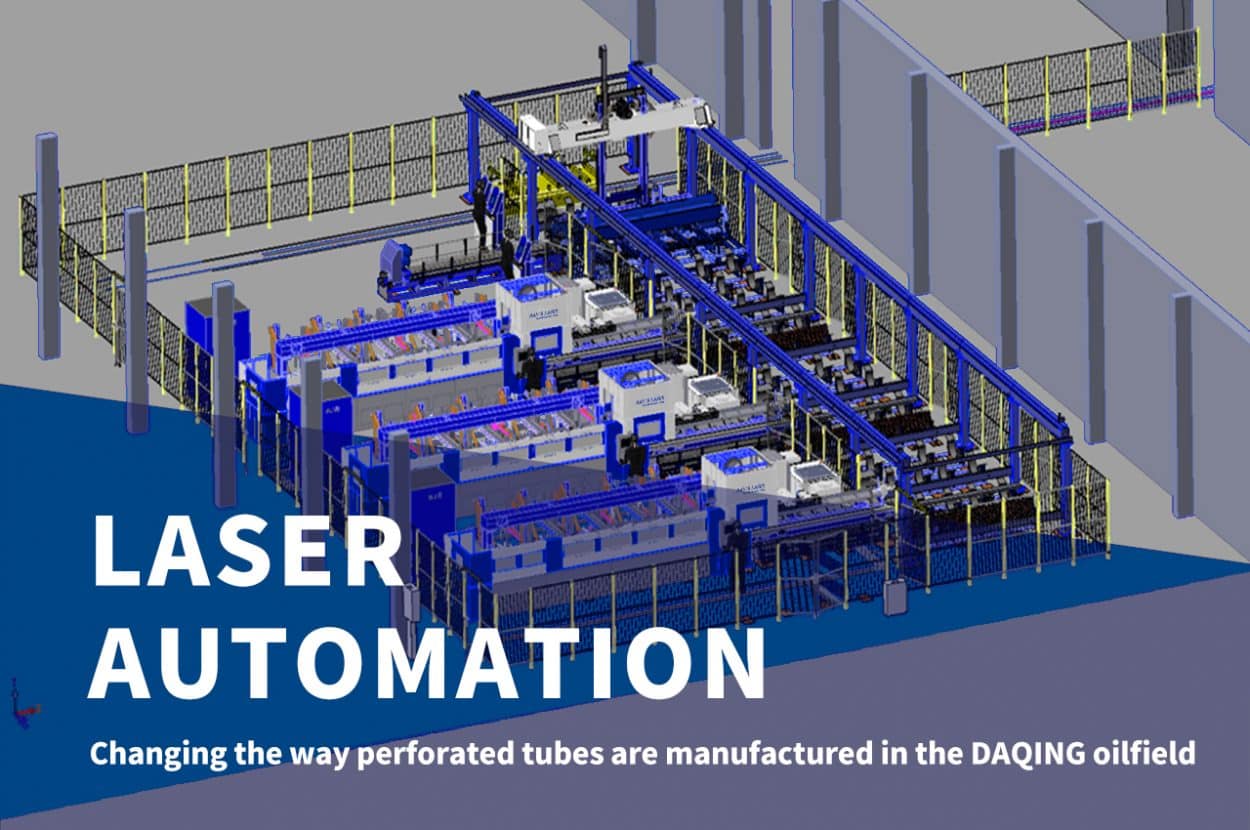

Han’s flexible manufacturing production line (Tube-type) combines an automated convey linked to tower storage for tubes. Tubes are automatically sorted, loaded, polished and unloaded. Semi-manufactured perforation tubes are then transferred for final welding or assembly by RGV convoy. The whole production line is equipped with a safety protection system as well as an audible and visual alarm system.

About Han’s Laser

Han’s Laser Technology Industry Group Co., Ltd (Han’s Laser; Chinese:大族激光002008:SZ), is a Chinese conglomerate, founded in 1996, and later listed on the Shenzhen Stock Exchange (SZSE) in 2004. Han’s Laser offers smart manufacturing solutions in the field of laser equipment, robots, and automation, mainly engaged in the innovation, manufacture and sales of core functional components including fiber lasers, control systems, laser heads, laser marking equipment, cutting and welding machines, PCB laser equipment, automatic robots, and automation. Its products have been widely applied in metalworking; new energy and power; electricity; measuring equipment and tools; wireless telecommunications; household and office furniture manufacturing; vehicle manufacturing; precision machinery; building construction; hardware manufacturing, etc.

Laser + X

Following the “Laser + X” strategy, Han’s Laser has been constantly expanding its business to new industrial applications and scenarios by launching competitive general components and industry-specific equipment. For over 20 years, Han’s Laser has mastered the core technology of fiber lasers, control units and laser heads, the major functional parts, to support the global manufacturing industry with turnkey solutions for laser processing and related infrastructure. Han’s Laser combines multiple advanced technologies and inspires laser innovation by offering custom laser-related applications and solutions.

For more information, visit at: www.hansme.net