The COVID crisis has highlighted the need for protective masks to fight the virus. But long before surgical masks and N95 respirators became part of our daily lives, face masks were already in daily use in the industry.

With the coronavirus pandemic and the obligation to wear filtering facepieces decreed in many countries, two families of masks have been popularized: surgical masks and FFP respirators /N95 masks.

If a surgical mask is a disposable medical device only used in the medical field, the respirators used in industry are personal protective equipment (PPE) and offer respiratory protection.

What are the different types of respirators? How do they offer protection? Which respirator for which applications? How to wear a facepiece? Our article will give you some piece of advice to help you choose the most suitable equipment for your industrial needs. We will only focus on PPE. If you want to know more about medical masks, read this article.

In the industry, filtering facepieces are mandatory for anyone working in a dusty environment with exposure to hazards (fumes, gases or other toxic substances). They protect the wearer from all particles and projections that could be inhaled and prevent him/her from harmful consequences for his health.

RELATED ARTICLE

Insulating and Filtering Masks

Different types of industrial equipment exist, insulating masks and filtering masks. Choosing one instead of the other implies taking into consideration the type of contaminant the wearer is exposed to and the oxygen level in the work environment.

Both filtering and insulating masks offer protection against dust, gas, fumes, vapors and aerosols. While the filtering ones are equipped with filters that retain contaminants and purify the air breathed by the user, insulating masks are supplied with air that originates from an uncontaminated source. Therefore, they offer superior protection to all other masks because the user is permanently isolated from the contaminated area.

Insulating Masks

Insulating masks are essential for long-term work in confined environments (for example in sewers), with low oxygen levels (below 17%), or when the concentration of the contaminant is too high and the contaminant cannot be filtered.

Those full face masks protect the eyes, the nose and the mouth and can be self-contained or non-self-contained.

- With a self-contained device, the user carries an oxygen cylinder connected to the mask via a hose. The user is therefore free to move around the work area. The device does not involve a filter so the user is constrained by the duration of the cylinder’s autonomy.

- With a non-autonomous device, the user has a supply of clean air via a hose connected to a compressor located outside the polluted work area. He is therefore permanently connected to this hose and must therefore be more careful with his movements.

Filtering Masks

Filtering masks can only be used in oxygen-rich environments (with oxygen levels above 17%) and are suitable for short-term work.

- The most famous ones are the FFP1, FFP2/N95 and FFP3 respirators.

- These single-use filtering facepieces protect against contaminants such as dust, particles or viruses with a maximum use time of 8 hours.

Wearing a respirator can be very uncomfortable (heat inside the mask, breathing resistance). Some masks are equipped with an exhalation valve that improves the user’s comfort. This valve allows air to pass through when breathing out and closes when breathing in. Particles do not penetrate the mask, but the exhaled air is not filtered and can therefore contaminate the outside environment.

The Mask Efficiency Classes

| Protection Class | FFP1 | FFP2 | FFP3 |

| Contaminant | Non-toxic fine dust Silica, Graphite, Sulphur, Coal, Ferrous metals, Glass wool, Wood | Fine and toxic particles Resin, Metal, Oil mist, Viruses | Very fine particles Asbestos, Arsenic, Ceramic fibers, Concrete, Viruses, Chromium, Nickel |

| Applications | The textile industry, Metallurgy, Mining | The textile industry, Welding, Metal cutting, Laboratory work, Agriculture (bird flu) | Short-term work in contact with asbestos or legionella Effective against pollution Welding, Cast iron, Metal cutting, Pharmaceutical industry |

| Filtration Efficiency | 80% | 94% | 99% |

Full and Half Masks

Depending on the type of pollutants and their concentration in the work environment, the wearer can choose either a half a full mask.

Half Masks

Half masks are filtering equipment that protects the respiratory tract (nose, mouth and chin) without compromising the field of vision. They are effective against dust and particles and are sufficient in environments that are not hazardous to the eyes.

- Soft silicone half-masks are reusable, offer comfort to the user and can be worn for long periods.

- Lighter, disposable half-masks contain neither latex nor silicone but allow the user, thanks to their low nasal position, to wear safety glasses for example.

Full Face Masks

Full face masks protect the nose, mouth and chin and in addition cover the eye area. They are recommended when there is a risk for the eyes as they guarantee a good seal and maximum protection for the operator.

They are effective against toxic gases, fumes and vapors in oxygen-rich (full-face filtering masks) and oxygen-poor (full-face insulating masks) work environments.

- Single-filter full-face masks are made of elastomer or silicone. Some models are equipped with a panoramic screen for a better field of vision.

- Double-filter full-face masks are equipped with a double air filter system with a valve that allows air to escape better. This provides greater comfort for the user and also prevents fogging.

Full face masks are widely used in the chemical, pharmaceutical, automotive and gas industries.

Whether you choose a full-face mask or a half-face mask, you will have to choose the right filters. There are 3 types of filters: gas filters, particulate filters and combination filters.

- Gas filters protect against toxic vapors, gases and chemicals.

- Particle filters protect against dust, smoke, steam, microorganisms and viruses.

- Combination filters combine the characteristics of gas and particle filters and are required, for example, to protect against aerosols and vapors.

What are the Standards?

Respirators are tested in the direction of inspiration (from outside to inside). The tests take into account the efficiency of the filter and leakage to the face.

In Europe, they must meet the European standard EN 149: 2001 which has three classes of disposable particulate respirators (FFP1, FFP2 and FFP3).

- FFP1 refers to the least filtering of the three masks with an aerosol filtration of at least 80% and leakage to the inside of maximum 22%. This mask is mainly used as a dust mask (home renovations and various types of work).

- FFP2 masks have a minimum of 94% filtration percentage and maximum 8% leakage to the inside. They are mainly used in construction, agriculture, and by healthcare professionals against influenza viruses.

- >> FFP3 masks are the most filtering mask of the FFPs. With a minimum filtration percentage of 99% and maximum 2% leakage to the inside, they protect against very fine particles such as asbestos.

In the United States, respirators must meet NIOSH (National Institute for Occupational Safety and Health) standards. Within this standard, there are several classes of respirators depending on the degree of oil resistance:

- Class N: no oil resistance. A distinction is made between N95, N99 and N100. The number after the letter indicates the percentage of filtration of suspended particles.

- Class R: mask resistant to oil for up to eight hours. Here again, a distinction is made between R95, R99 and R100.

- Class P: a completely oil-resistant mask. There are also P95, P99 and P100.

How to Wear a Face Mask? The Importance of Fit Testing

Filters are essential to ensure a respirator offers the right protection and filtration efficiency. But that is not all. A face mask must also be worn correctly to guarantee full protection and minimum leakage. When badly worn, even the best respirator becomes meaningless.

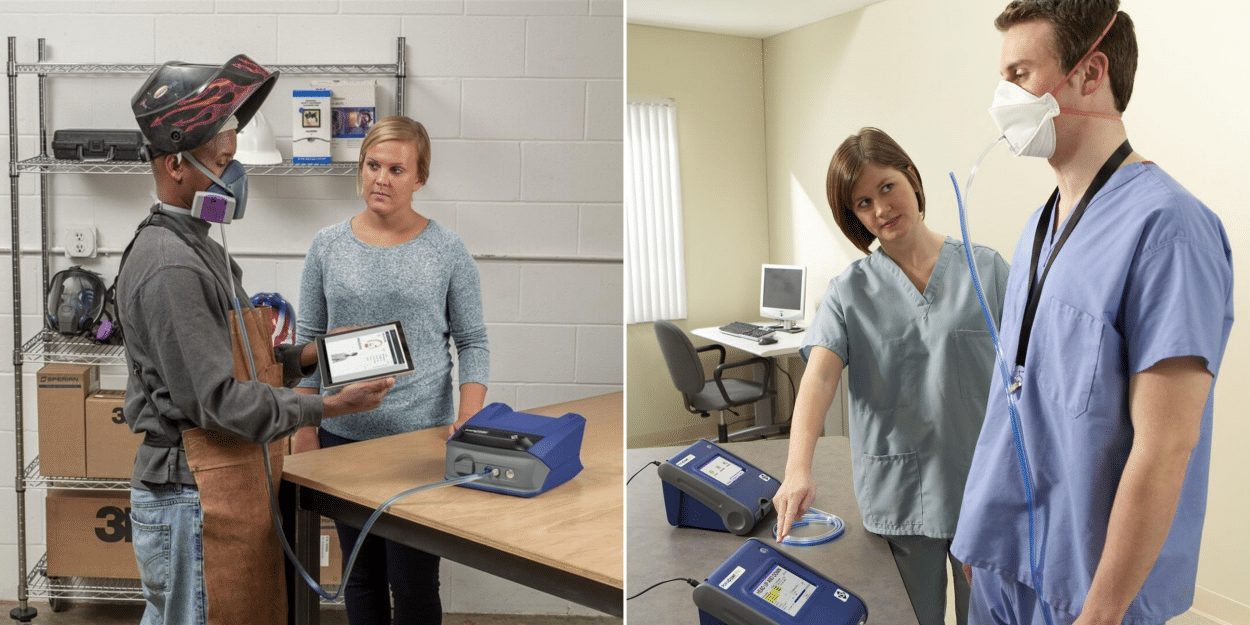

Fit testers are here to make sure that respirators fit well on a person. American company TSI manufactures quality instruments among which is the PortaCount Respirator Fit Tester 8040. Last year, we spoke with Oliver F. Bischof, Director of Sales – EMEA at TSI:

“Respirators and filtering face pieces differ by type, by brands, by model and by size. And not every model fits a person. So even the best respirator may not offer adequate protection depending on how tightly it fits your face and how well it seals. There could, for example, be leakage around the edges of the masks or around the nose. So a high filtration efficiency can be meaningless if the mask is leaking.”

Their fit tester shows the person being fit tested all the instructions on a screen.

‘It walks the person through the entire process of putting the respirator on, doing the exercise, and the test. The machine even allows you to do the testing yourself, although we recommend that any fit test is done by a competent person. We have a fast fit protocol that does the testing in 2.5 minutes.”

Many countries follow standards that demand that everybody who wears a respirator for work has to be fit tested. In the United States and in the United Kingdom, every operator who needs to wear a respirator for work has to be fit tested. In France and in the Netherlands, only the people working in the asbestos removal and cleanup industries have to be fit tested.