Cleanliness classifications, such as ISO 4406 or DIN 51455 for hydraulic and lubricating fluids, provide important information about product quality. The demands on the performance and reliability of these high-quality fluids will increase. State of the art analysis methods, such as visual microscopic examination combined with “laser-induced breakdown spectroscopy” (LIBS) used with a seamless workflow and a single system can help users meet the requirements of ever-stricter quality standards.

Article written by Bernhard Schroth, James DeRose (PhD), Dr. Kay Scheffler, Dr. Konstantin Kartaschew

Particulate contamination present in hydraulic or lubricating fluids can cause malfunctions or damage to mechanical systems. For high-precision systems, like turbochargers used in car, boat, and airplane motors, quality control of the fluid contamination that occurs during the manufacturing process is done. The fluid is filtered before use and any particles found further analyzed. For most mechanical systems, such as gearboxes of engines and motors or turbines used for offshore wind parks, quality control of the fluid contamination is done after use where the fluid is collected, filtered, and then the particles analyzed. Normally, for both cases, the size of each captured particle is measured and the number of particles determined. The resulting particle size distribution is converted into a comparable and usable form using standardized methods.

ISO 4406 and DIN 51455 define classifications for the degree of particle contamination present in hydraulic fluids and lubricants [1,2]. The analysis of particles present in a liquid can be carried out directly on the liquid using electronic or light scattering or extinction methods [3,4] or the particles can be analyzed with a microscope after filtration [2,5].

A complete classification code based on particle analysis with a microscope from ISO 4406 or DIN 51455 would be −/X/Y [1,2]. Each value, X or Y, represents a position in a table of 30 specified particle quantities which correspond to the number of particles within a reference volume of 100 ml [2] or 1 ml [1]. Each ISO/DIN code value is assigned a particle count range based on whether the particle size is: ≥ 5 µm (X) or ≥ 15 µm (Y) [1,2].

Let’s take as an example the code −/16/14. The value 16 stands for a total particle count between 32,000 and 64,000 for particles with a size ≥ 5 µm in a fluid volume of 100 ml (equivalent to 320 to 640 particles per 1 ml). It also means that the fluid contains up to 64,000 particles ≥ 5 µm per 100 ml. The example code also says that the analyzed fluid contains between 8,000 and 16,000 particles with a size ≥ 15 µm in 100 ml (equivalent to 80 to 160 particles per 1 ml).

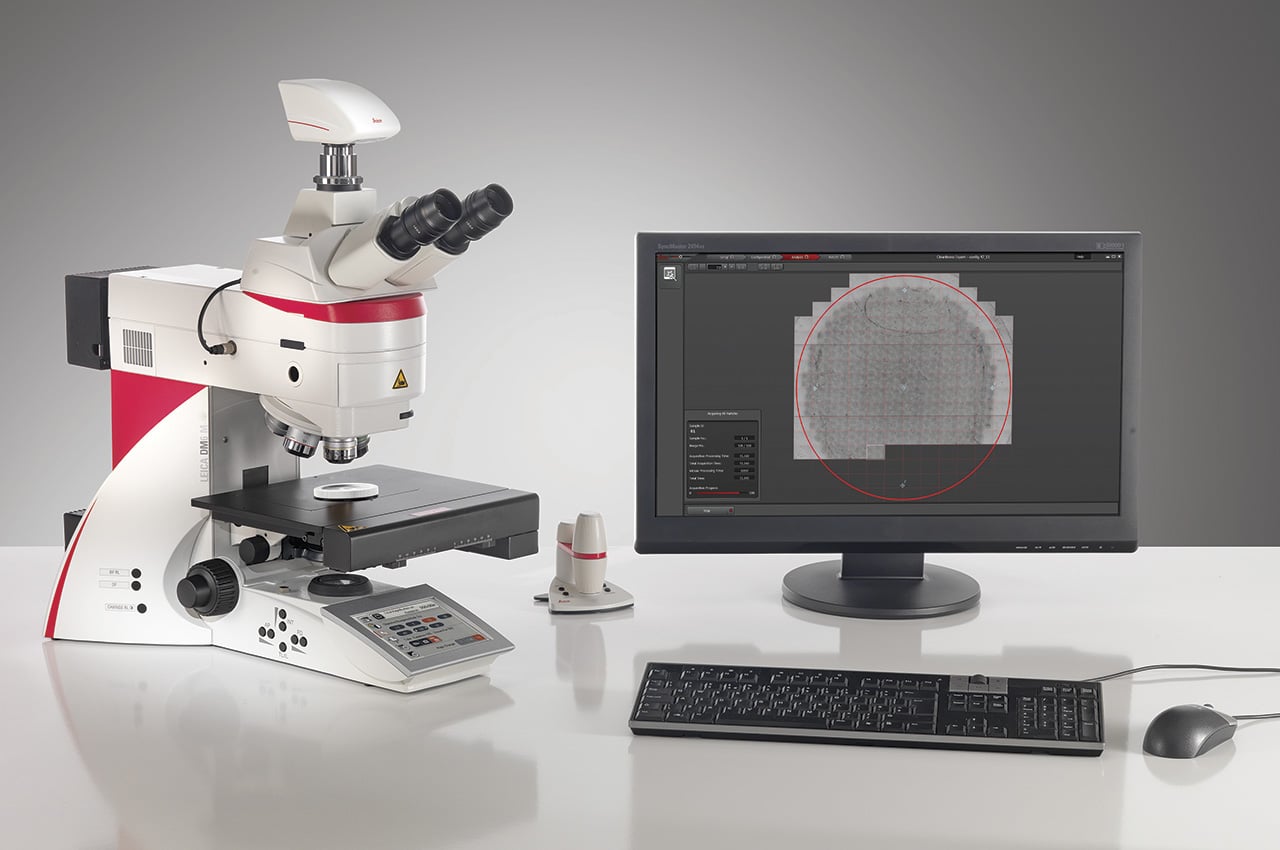

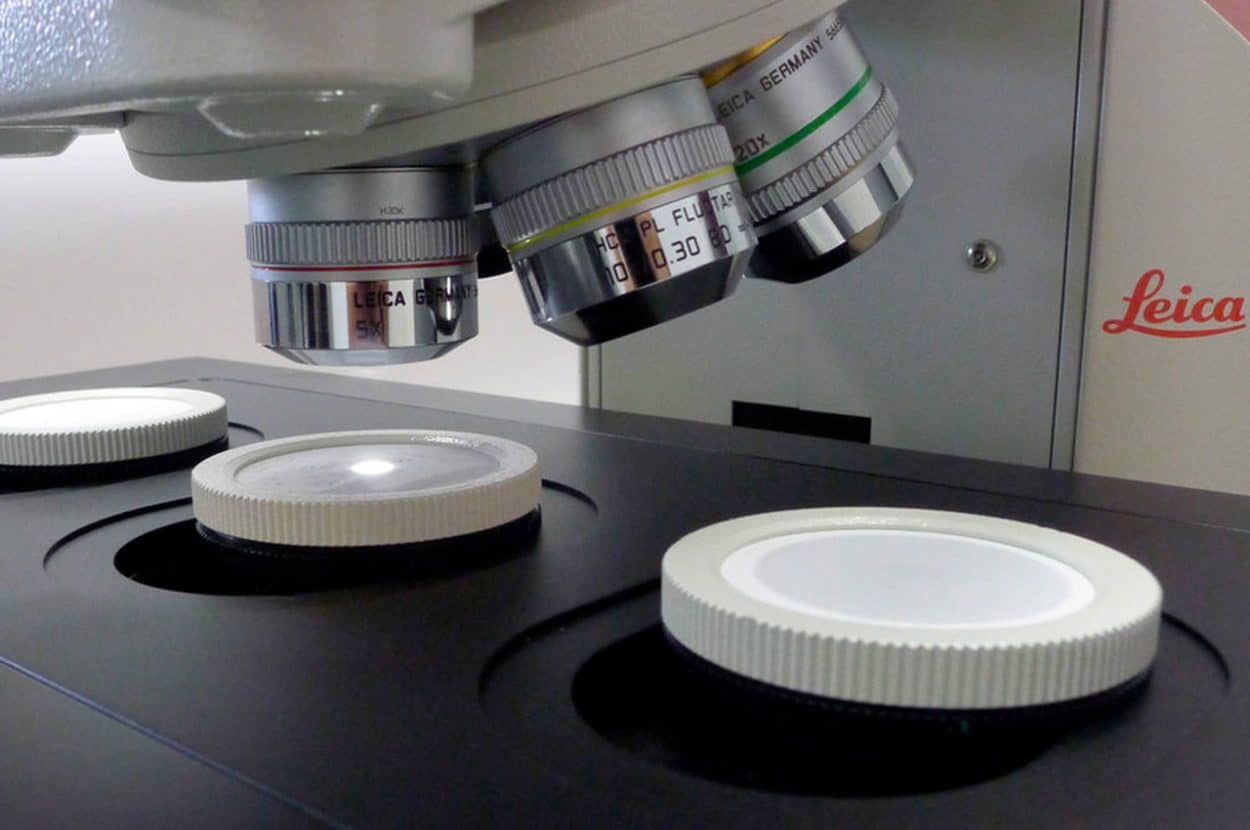

A filter analysis in accordance with ISO 4406 and DIN 51455 can be carried out with a microscope system using a motorized scanning stage, such as the DM6 M. The automated visual filter evaluation which can be done with the Cleanliness Expert software and DM6 M microscope from Leica Microsystems has specific advantages. In addition to the particle sizes, the visual evaluation provides valuable data on the morphology and type of particle. So numerous metallic and non-metallic types of particles can be differentiated. The Cleanliness Expert software delivers analysis results done in accordance with ISO 4406 or DIN 51455. Reports and documentation of the results can also be created quickly and easily.

There are always growing demands on the performance and reliability of technical systems and components. Current requirements of applicable standards can be reliably fulfilled, but what will they look like in the future? Analysis methods that provide information about product quality beyond the current requirements of applicable standards will be able to more easily meet any future changes to the standards. One such system that seems able to keep up with future needs in this regard is the DM6 M LIBS materials analysis solution.

Based on the DM6 M microscope and the Cleanliness Expert software, the DM6 M LIBS is a powerful and efficient 2-methods-in-1 solution. In a seamless workflow, the particles on a filter are visually examined and then chemically analyzed using laser-induced breakdown spectroscopy (LIBS). The DM 6 M LIBS solution automatically optimizes raw spectroscopic data and identifies the material via a database search. The findings are listed in a table together with the spectra of the analyzed particle and the database reference spectrum. With the DM6 M LIBS system, common metals, such as iron (Fe), copper (Cu), or zinc (Zn), as well as single alkali like sodium (Na) or lithium (Li) and alkaline earth metals like magnesia (Mg) or calcium (Ca) can be easily detected.

Knowing the particle composition is a big advantage. It helps users to better estimate the potential of particles to cause damage. For hydraulic or lubricating fluids used in high-precision systems with the strictest tolerances, such as turbochargers, the source of particle contamination within the production process can also be narrowed down even further. Ultimately with greater technical cleanliness for hydraulic or lubricating fluids used in mechanical systems, the quality and reliability of products can be improved, system damage can be minimized, and industrial production processes can be even further optimized.

References

ISO 4406:2021 Hydraulic fluid power — Fluids — Method for coding the level of contamination by solid particles, International Organization for Standardization.

DIN 51455 :2020-12 Liquid petroleum products – Determination of particle number and particle size in oils, Deutsches Institut für Normung

ISO 11171:2020 Hydraulic fluid power — Calibration of automatic particle counters for liquids, International Organization for Standardization.

ISO 11500:2008 Hydraulic fluid power — Determination of the particulate contamination level of a liquid sample by automatic particle counting using the light-extinction principle, International Organization for Standardization.

ISO 4407:2002 Hydraulic fluid power — Fluid contamination — Determination of particulate contamination by the counting method using an optical microscope, International Organization for Standardization.