Since it was discovered in the UK in 2004, graphene—a single layer of carbon atoms, tightly bound in a hexagonal honeycomb lattice—has been used in an ever-growing number of applications. Now scientists at City University of Hong Kong (CityU) have used the so-called “wonder material” to develop an anti-bacterial face mask that has the potential to combat COVID-19 quickly, cheaply and sustainably.

This article was simultaneously published in MedicalExpo e-magazine.

The findings were published in scientific journal ACS Nano. Used the world over, ordinary surgical face masks are an important way of stopping the spread of COVID-19. However, viral particles can still settle and survive on such masks, which means that if they are touched or disposed of inappropriately, they can still cause infection.

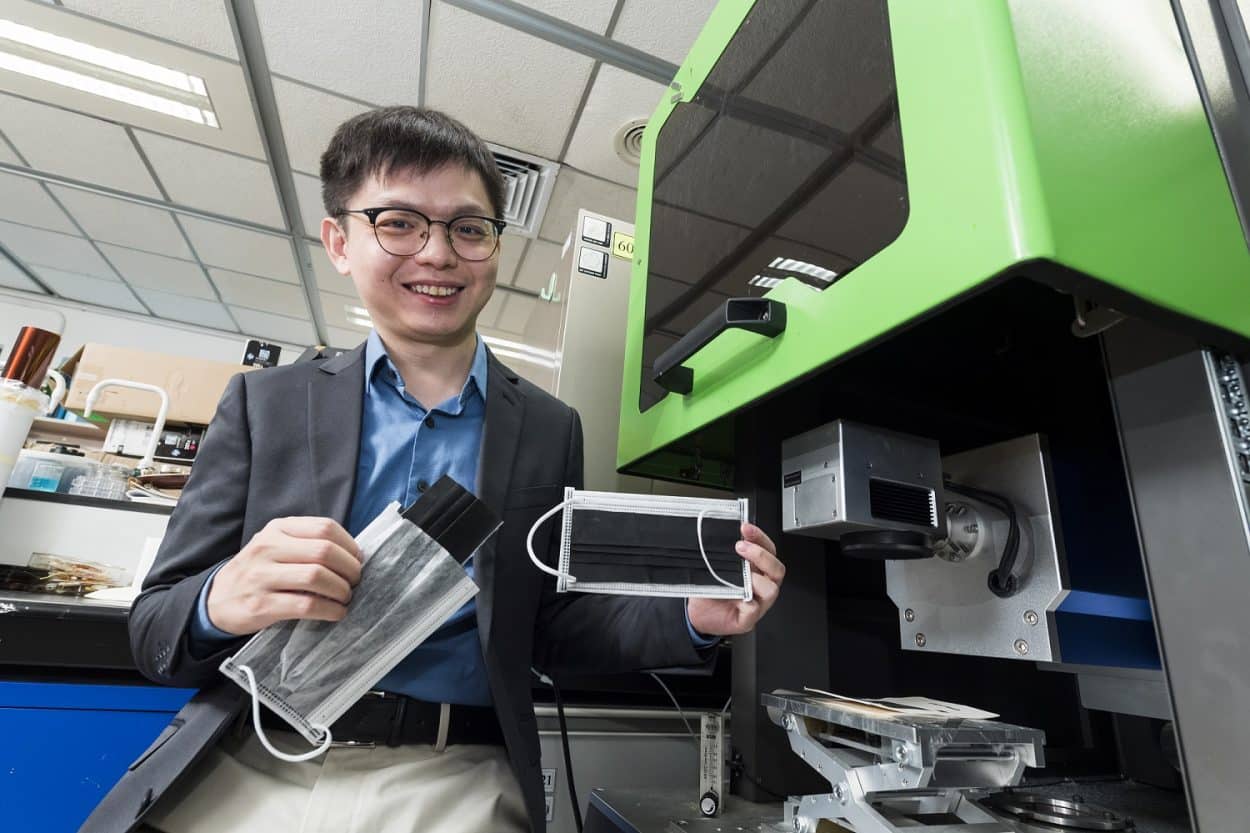

A research team at CityU’s Department of Chemistry (together with other partners), led by Assistant Professor Dr. Ye Ruquan, has now developed a mask made with laser-induced graphene. This has already shown significant antibacterial properties and may have potential against coronaviruses. In experiments with two types of human coronavirus, the masks deactivated 90% of viral particles in sunlight within just five minutes and 100% within 10 minutes. In addition to its antibacterial properties, graphene also generates heat when exposed to light, which helps with the decontamination process. Dr. Ye said:

“More research is required to determine the exact reason for graphene’s anti-bacterial nature. It may relate to damage caused to bacterial cells by graphene’s sharp edges, and possibly also to dehydration effects induced by graphene’s water-repellent properties.”

RELATED ARTICLE

Innovative Production

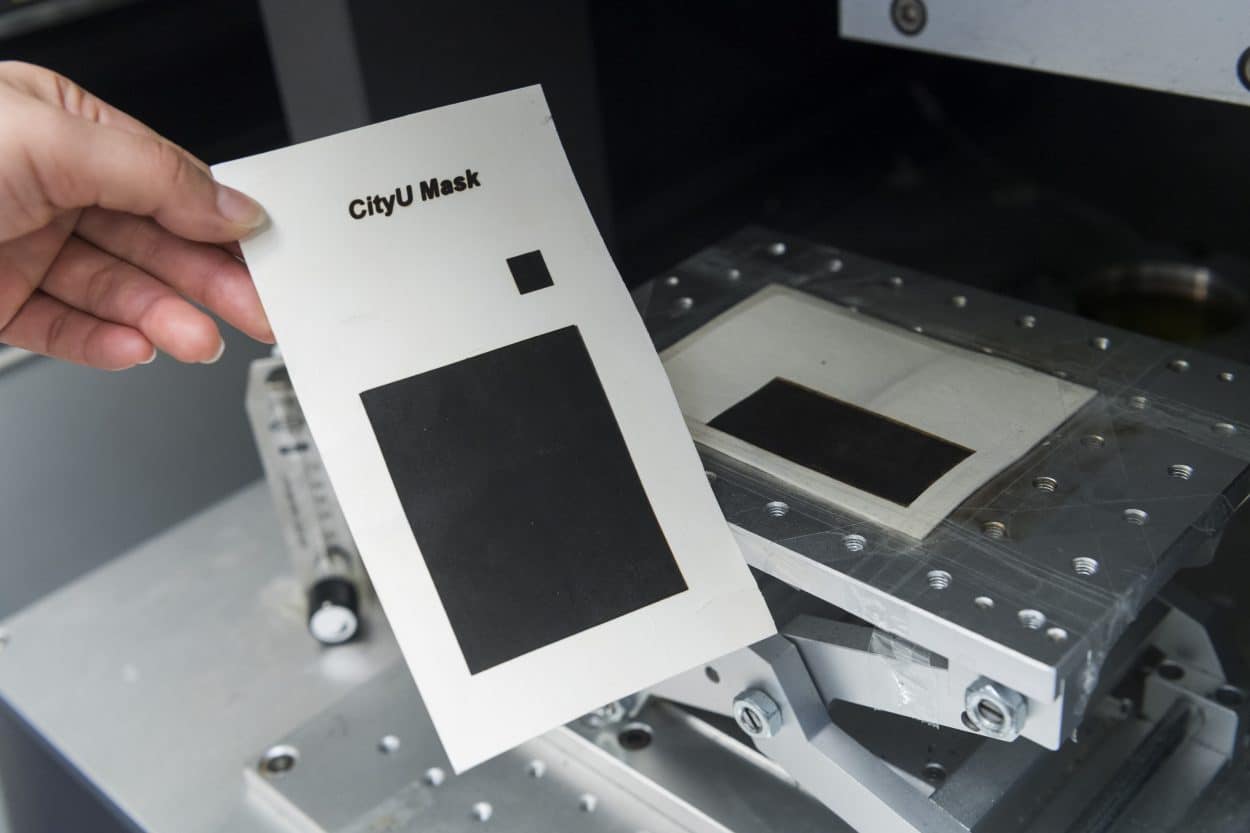

One of the most innovative aspects of the new mask is the way the graphene used in its construction is produced. Conventional methods for producing graphene typically have poor control over the shape of the product and require high-temperature conditions and lengthy synthesis routes, entailing high costs.

By contrast, producing laser-induced graphene is cheap and easy. Passing a laser over a 100cm² area of a carbon-containing material such as cellulose or paper for just 90 seconds can create the graphene necessary for the outer or inner layer of the mask, using a low amount of energy and no chemicals. Adjusting the power of the laser allows the size of the pores of the graphene to be controlled, giving the masks a breathability similar to surgical masks. Dr. Ye said:

“I think production streamlining should be simple and the price of each mask is expected to fall in between that of a surgical mask and an N95 mask. Moreover, laser-induced graphene masks are both reusable and biodegradable, lessening the impact of non-biodegradable disposable masks.”

Next Steps

The next step for the research team is to evaluate the antiviral efficiency of the graphene masks and develop a production strategy. The team envisions releasing the mask to the market shortly after tests have been certified. Dr. Ye explained:

“We are in contact with a mainland manufacturer which produces washable masks. We have decided to use a blend of graphene with cloth, because pure graphene is more difficult to scale up, and are currently testing prototypes.”