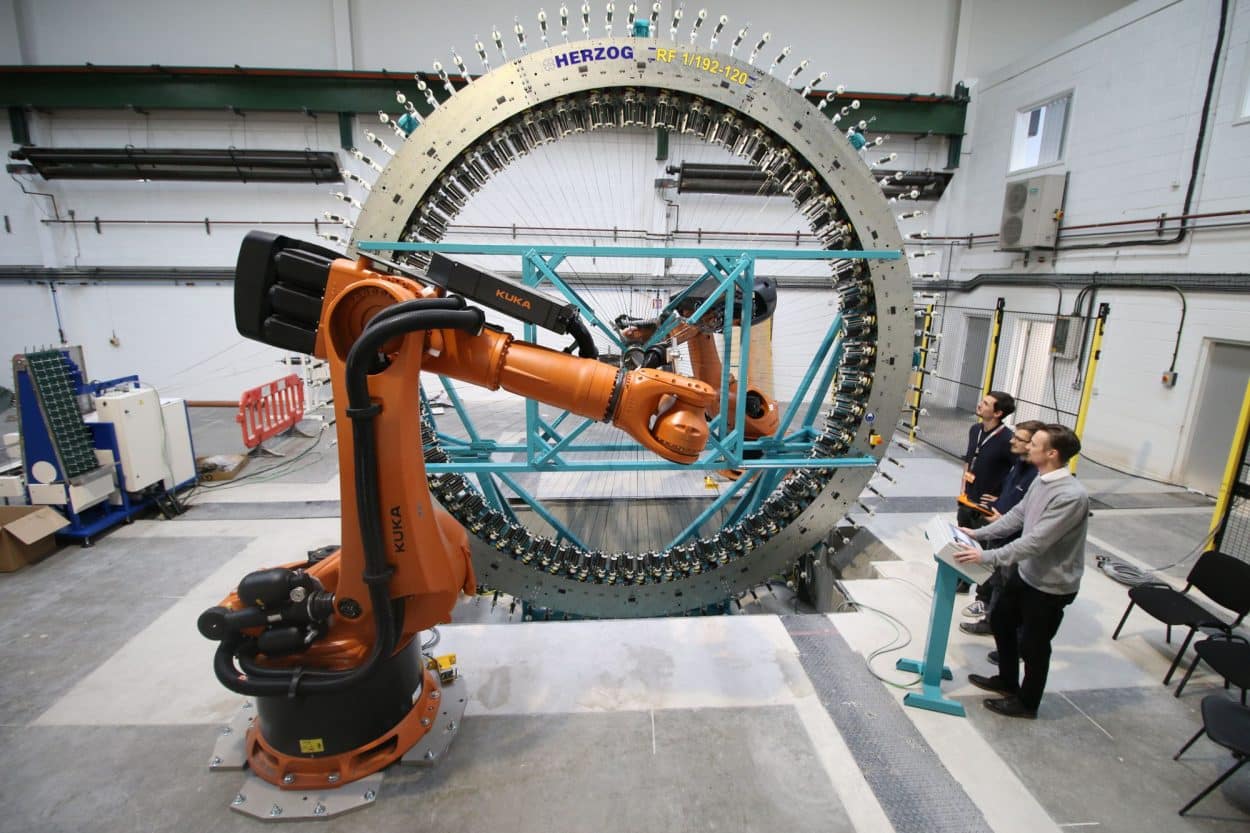

A giant robotic braider, capable of creating complex composite preforms for widespread lightweight applications, is up and running in the UK.

The University of Sheffield Advanced Manufacturing Research Centre (AMRC) bought the equipment, which is the largest in the country, to enhance its cutting-edge collection for the manufacture of automotive and aerospace components.

Chris McHugh, Dry Fiber Development Manager at AMRC, explains that the six-meter diameter, triaxial braiding system, manufactured by Herzog, functions with the assistance of two Kuka KR420 robots.

Braiding is not an uncommon process – however braiders of this size, and with two robots working together to create a composite structure is relatively unusual. In fact, it is my understanding that in the UK we are the only catapult center that has this capability of this size – and with two robots.

Enhancing Productivity

The AMRC is a network of world-leading research and innovation centers working with advanced manufacturers around the world to improve industrial performance.

Its other equipment for dry fiber pre-forming includes a 3D weaving loom, a tow-spreading machine and robotic end effectors for automated handling, explains McHugh.

Much of this was funded by the Aerospace Technology Institute to deliver this capability for AMRC and wider UK and European opportunities.

The braider can produce parts of up to 300kg in weight, 700mm in diameter and 2.8m in length.

It can be used to make axisymmetric parts such as tubes, pipes and pressure vessels up to a certain diameter, as well as non-axisymmetric parts including elbow parts and components with curvature or tapering sections.

We can also produce non-axisymmetric parts like T-pipes. These types of structures are used in aerospace even if they are not currently manufactured with this technology.

Teamwork

A wide range of materials, including carbon, thermoplastic, glass, aramid and co-mingled tows, can be used.

The braider is also capable of working with ceramic fiber, such as alumina and silicon carbide, which would be difficult to process on a conventional braiding machine.