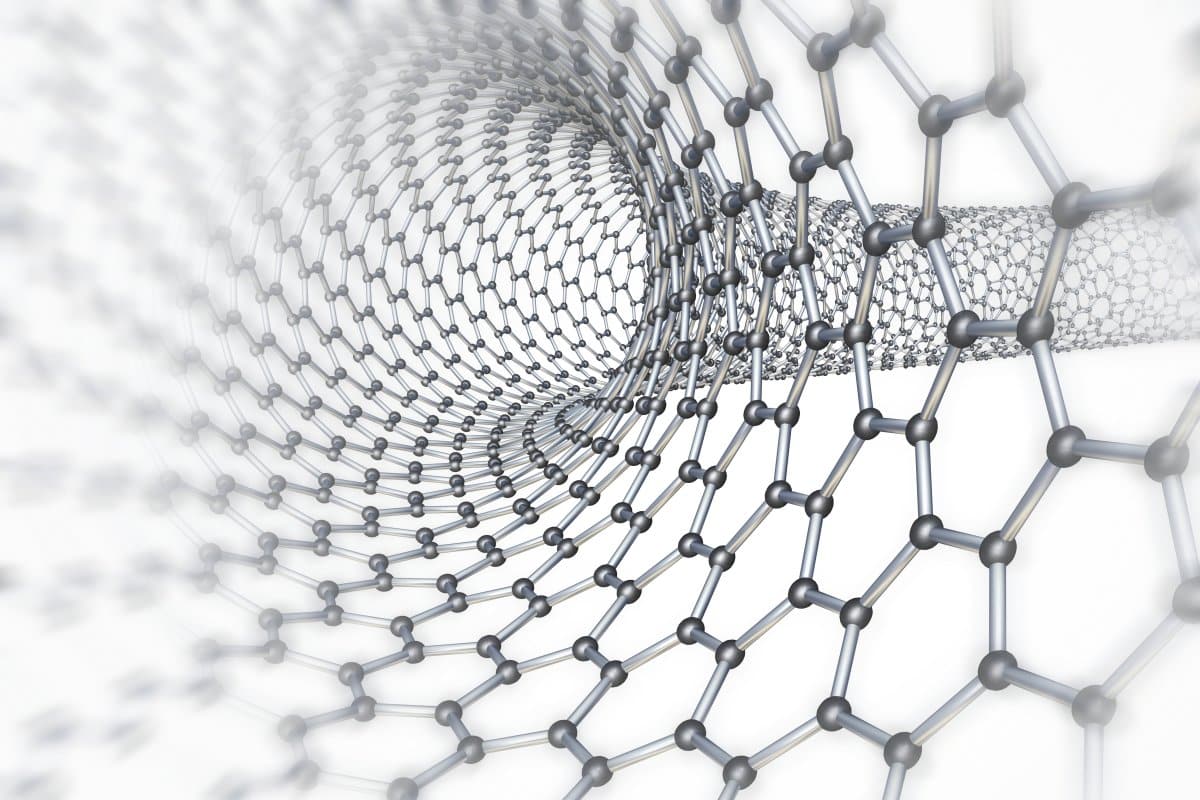

Since carbon nanotubes (CNTs) were discovered in 1991, numerous challenges have prevented them from fulfilling their industrial potential. But today’s carbon-based revolution may change that. Around 100 times stronger than steel, with great electrical conductivity, they are now found in everything from batteries to airplane wings, and may soon make possible faster computers, ultra-efficient smartphones and numerous miniature energy-harvesting devices.

An atomic-scale carbon cylinder with a diameter of one or two nanometers, the CNT is a supermaterial with a huge range of industrial applications. Boston’s Inkwood Research predicts the value of the CNT market will exceed $9 billion by 2024, up from $1.7 billion in 2016.

Energy a Go-Go

At one ten-thousandth the size of a human hair, CNTs are invisible to the human eye. But their miniscule size belies their might. Gather a few billion together and they can radically improve everything from solar cells to batteries.

Researchers at Rice University in Texas have designed a new type of battery that can store far more power than current lithium-ion versions (LIBs) by using an anode made from a seamless hybrid of graphene and CNTs. The anode’s nanotube “forest” maximizes the surface area for lithium particles to slip in and out, as the battery charges and discharges.

Research team leader Dr. James Tour explains:

We are currently scaling the technology for commercialization. The aim is for sales in 2019. First generation batteries will have three times the capacity of present LIBs and charge in about 10 to 15 minutes. This could dramatically open up the electric car market.

CNTs are also found in the carbon-ion supercapacitors of Oxford-based start-up ZapGo, whose portable charger will hit the market in 2018. Based on a combination of CNTs and graphene sheets, together with a proprietary electrolyte, these ultra-fast energy packs will charge from empty to full in less than five minutes.

ZapGo’s next goal is to produce a CNT/graphene-enabled supercapacitor to replace LIBs in mobile devices. For ZapGo’s investment and marketing director Simon Harris,

We still need substantial investment funds and better laboratory facilities, but we are aiming for development by 2020. Imagine a phone you can charge in five minutes. This supercapacitor will be a real game changer.

Life After CMOS

The quest for faster, smaller, more energy-efficient and more reliable computer chips may also involve CNTs. Research teams around the globe are now showing that CNTs—with their one-nanometer scale and superior electrical conductance—offer advantages over silicon-based complementary metal-oxide semiconductor (CMOS) transistors.

Shu-Jen Han of IBM’s Thomas J. Watson Research Center in New York says:

Silicon chips could hit their power and performance limit at seven nanometers. While the recent announcement of five-nanometer silicon nanosheet transistors may herald an increase in scale, power and performance, any improvements will be limited.

IBM researchers recently announced the creation of a CNT-based processor capable of operating at speeds of up to 2.8 GHz. With further development, such processors might perform five times faster or use five times less energy than their silicon-based counterparts.

While scalability and widespread integration are still major hurdles, commercially available CNT-based chips could lead to substantial gains in the bandwidth of wireless devices, resulting in faster communication and processing speeds for devices such as smartphones and laptops.

Aeronautical Applications

While the advanced composite materials used in today’s airliners offer significant weight savings, they are also vulnerable to cracking. Researchers have recently found that “stitching” such composites together with CNTs can make them much stronger and far more damage-resistant.

The researchers grew tiny forests of carbon nanotubes on films, which they then interspersed between layers of carbon fiber composites. The nanotubes, resembling vertically-aligned stitches, extend into the carbon laminates, holding them together far more effectively.

Research leader Dr. Roberto Guzman explains:

A lot more work needs to be done, but I am confident these results will eventually lead to stronger and lighter planes. That means increased fuel efficiency and a reduced environmental footprint.

The integration of CNTs into composites also boosts conductivity. A lightweight, low-power CNT-based ice protection system for aircraft will be flight tested by the end of next year by North Carolina’s UTC Aerospace Systems. According to the company, the CNT heater layer is up to 40 times lighter than conventional electrothermal elements, and requires up to 50% less power.