Cloud ERP is one of the most sweeping upgrades in manufacturing technology. At a time when on-site systems often have trouble dealing with sensor data and the new challenges of the IoT, the cloud offers a solution.

Cloud ERP has become one of the most radical, sweeping upgrades in manufacturing technology. For Pat Garrehy, CEO of US-based Rootstock Software, companies that implement a cloud ERP solution are seeing cost reductions in both IT staff and hardware infrastructure.

Cloud ERP deploys faster, it’s easier to use and access to information is from anywhere, at any time and by any device. The pricing of a cloud system is more attractive because the up-front costs of typical on-site ERP systems are deferred and spread over the life of the use of the software.

The company’s solutions include manufacturing, distribution and supply chain apps which integrate out of the box with Sales Cloud by salesforce.com and other ERP and CRM applications on the Salesforce platform.

Challenging Times

For years, on-site ERP has provided the functionality manufacturers required.

But on-site ERP systems are no longer able to handle the challenges presented by today’s IoT data—for example, from machining equipment sensors—or the required connectivity and access.

Many manufacturers are using ERP systems that are up to 30 years old, despite the fact that their markets have changed due to altered business and consumer demands. Not only have they had to adapt to a global environment, but collaboration throughout the supply chain via a variety of mobile devices is now the norm. Mr. Garrehy says:

While they limped along with their legacy ERP software through the global business changes, they are now choking because their legacy on-premises solutions have not been, and cannot be changed to meet this rapidly changing social and collaborative environment.

But the cloud offers a solution, he adds:

Data is stored in the cloud, not on big, expensive hardware installed in a single location. Internet access means that data can be instantly viewed, analyzed and shared at anytime from anywhere, including mobile devices. Firms no longer have to rely on large, expensive and cumbersome IT departments to manage these systems.

Cloud ERP does, of course, rely on the internet, but problems with connections are becoming increasingly rare, he suggests.

Everyone has internet these days, and Rootstock has customers in North America, Europe, Africa, Asia and Australia. Reliability was an issue, of course, in years past. But it seems to me that we now have more problems with the hardware going down or electricity outages than internet problems.

Industry Specific

New York-headquartered Infor offers custom responses through its CloudSuite. Company vice president Phil Lewis says industry-specific solutions can be taken down to the micro level for individual customers, and then continuously enhanced.

We created these suites of apps, and in the last two to three years have invested in taking them into the cloud, powered by Amazon Web Services. Now, in every industry, we’re seeing far greater numbers [of firms] than we expected seeking to move this way. In France, Germany, the UK and North America there is very clear movement towards the cloud.

The apps have been built and developed to meet the specialized needs of industries ranging from aerospace and defense to industrial machinery and food and beverage. They offer end-to-end solutions encompassing everything from front office activities to mission-critical core functions and industry-driven analytics—all within one system.

Especially high demand is coming from customers in the automotive and industrial machinery sectors, where customers appreciate the benefits of a system that can be accessed from anywhere and which allows them to perform multiple functions. In the industrial machinery realm, for example, the app allows the user to configure and price products, manage complex projects, streamline production, coordinate with global suppliers, manage factory floor activities and oversee service operations.

Initially there was wariness across all industries, Lewis admits. Customers were concerned about security and having to rely on a partner to protect the “crown jewels of their company.”

But they are realizing they can have confidence in working with Infor coupled with Amazon; that it offers more flexibility and opens up new opportunities to them.

Up to the Job

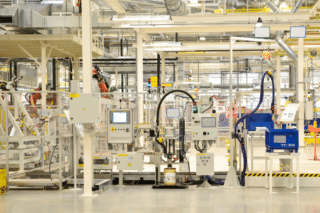

The best time to consider the cloud is from start-up, suggests Matthew Thomas, supply chain manager of Vantage Power. Based in the UK, the young company produces complete hybrid powertrains for bus OEMs as a retrofit solution for vehicles already on the road. Vantage went live with its Infor CloudSuite system in June.

We took the view that if we put it in place right from the beginning of the product’s life, then it would not have to be done retroactively. We needed a system that could grow with us, so that when we’re working across multiple sites in the future, it will be up to the job. [Another advantage] was having the ability to access data from a laptop while out visiting a supplier or customer.

The system, which can be accessed from any web browser, is currently being used to manage the company’s finances, orders, sales and warehouse inventories. And on the production side, the results are there:

We can allocate stock to particular orders and save ourselves time without having to find out where parts are. And there will be increased functionality as we move forward. It permits live access to real-time data while at customer or supplier premises. If your customer wants to increase the order, CloudSuite calculates when you can ship the higher quantity and highlights any blockers that might constitute a problem.

Or, if a supplier has a materials shortage, you can view the effects immediately, assess the impact and focus efforts on a solution.

Hybrid Solutions

Manufacturers know that to succeed in today’s evolving markets, they need a system that allows them to be agile, active, mobile and connected to the real-time data they need, agrees Mr. Garrehy.

More and more firms are moving toward a hybrid ERP solution that combines their existing legacy on-site system with cloud-based ERP software. Such a hybrid solution that meets each firm’s particular business would be considered part of a postmodern ERP strategy.