Smart sensors, X-rays, infra-red light, terahertz waves. How can industry see the invisible?

Examining the invisible is a major challenge for industry. This includes peering into the hidden innards without destroying a product and measuring volume and surface thickness, whatever the material. It is vitally important to inspect what cannot be seen before a product is launched on the market.

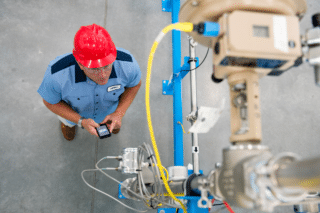

THE SMART INSPECTOR

Regular inspection of vehicles and industrial facilities is required to keep systems functioning and protect workers and the public. Detecting wear and structural damage in everything from aircraft parts to pressure vessels is a long and complex process. Fraunhofer has introduced its 3D SmartInspect sensor for non-destructive testing and quality control. It streamlines procedures, ensures complete coverage, verifies data and stores information in easily-retrievable form. Such a system also could reduce the need for ultra-qualified inspectors. Designed for use with tablet, smartphone or augmented reality glasses, SmartInspect indicates which areas of the object already have been inspected and verifies data acquisition. Defects appear in red on the display, facilitating rapid analysis and decisions regarding repairs. Digitizing data reduces downtime, and a digital testing memory improves management, providing economic benefits.

DRILLING WITH X-RAYS

Industry is also relying more and more on non-destructive imaging technologies. X-rays measure density and can see through a wide range of materials, including metal. The item to be measured is exposed to a beam of primary X-rays, becomes excited and emits secondary X-rays. The analyzer measures the intensity of energy emitted by these secondary rays, enabling it to provide data on the composition and the thickness of the test item. X-rays are therefore used for testing objects that exit the factory floor and increasingly for maintenance, for example, to inspect airplane tires for defects.

Bruker’s S1 Titan, a 1.5-kg handheld X-ray analyzer, can test connections soldered on aircraft circuit boards.

HOW TO SEE INVISIBLE HEAT

Thermal imaging inspection is another measurement method used on the test bench.

Infrared cameras can detect invisible heat and determine if an electrical product is generating abnormal temperatures due to resistance before market release.

Flir has developed a test bench camera dedicated to product inspection. The T660sc camera captures images from different angles and can read hidden areas. It can detect temperatures from -40°C to 2000°C with +/-1% accuracy. The camera calculates the temperature of the whole captured image rather than at isolated points, and can reveal temperature differences of only 0.035°C.

Flir’s camera can be used to test and inspect electrical equipment as well as water pumps. The camera can indicate a risk of overheating by measuring the temperature within the pump. For example, excess temperature might indicate the absence of water.

EXPLORING NEW METHODS

The electromagnetic wave spectrum has not been completely explored and certain wavelengths are used infrequently or not at all. This is the case with terahertz (THz) radiation. These electromagnetic waves, situated between infrared light and microwaves, have long been neglected for lack of detectors. Their use is rising today with the potential of THz imaging for non-destructive, contactless inspection.

Alphanov developed TeraCam, a cost-effective 2D camera equipped with a converter turning THz radiation into temperature readings.

Such devices can be employed in applications similar to those for infrared radiation. The waves can penetrate numerous opaque, non-conductive materials such as plastics, ceramics and wood, and can even detect humidity inside an object. Of particular interest is their not-ionizing characteristics, making them harmless to humans. For example, they have been tested recently in passenger inspection experiments at a Russian airport.