Andrea Sega is a 26-year-old engineer working for Northype Laboratories. With two colleagues, he built Adam, an all-in-one 3D printer. Adam combines in a single unit the functions of a 3D printer, a 3D scanner, a laser cutter/engraver and a CNC milling machine. DirectIndustry e-magazine talked to Sega about the invention.

DirectIndustry e-magazine: Can you introduce us to Adam?

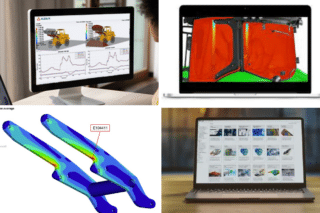

Andrea Sega: Adam is a printer that combines many machines—mechanical milling center, laser cutter, 3D printer—in a single unit. It consists of a modular platform including a sturdy Cartesian mechanism adaptable to any situation and a carriage holding the working tools. But the innovative parts are the working tools and the hardware and software control system. We offer a platform into which you can insert various additional modules. So everyone can customize the working head for their own use.

DirectIndustry e-magazine: Which materials can the modules handle?

Andrea Sega: There is no restriction. Our extrusion system can print all types of materials, from flexible ABS, TPU and TPE to harder and special filaments like carbon loaded materials, laywood or nylon. We optimized the additive technology function. The 3D printing module has a 0.4 mm nozzle and uses 1.75 mm filaments. And we provide a closed hot chamber to maintain a constant temperature inside, reducing printing errors. The laser module enables you to cut paper and cardboard, and also incise materials, such as polystyrene, MDF and leather.

DirectIndustry e-magazine: Can Adam also machine?

Andrea Sega: This was a big challenge for us! We managed to integrate an end mill in our printer. This allows you to create low-cost printed circuit boards and to create 3D objects with materials unsuitable for extrusion, such as wood and polystyrene. The Adam build volume is 16 x 16 x 27.5 cm. Adam plus, the premium version, brings the biggest ideas to life: 30 x 30 x 47 cm.

DirectIndustry e-magazine: Adam is also equipped with a 3D scanner, isn’t it?

Andrea Sega: One of the functionalities is the scanner. It can digitize real objects, which then can be replicated and modified thanks to very user-friendly modelling software. With our scanner, it is even possible to scan various fragments, put them together again and print the entire object!

DirectIndustry e-magazine: For which industries is it designed?

Andrea Sega: It is a very flexible machine, thanks to its endless functionalities, so it is perfect both for the artisan and the industrial-scale manufacturer. But also for those who don’t have the possibility of buying ten different industrial machines. They can get all of them just with a single machine.

DirectIndustry e-magazine: What’s its price?

Andrea Sega: It starts from 899€, with the 3D printing head alone, to 1750€ with the full range of working tools.